|

Once the whole floor was covered, I then cut out all the

bolt holes that would be used for the seats and harness so now we're

ready for some carpet.

|

|

|

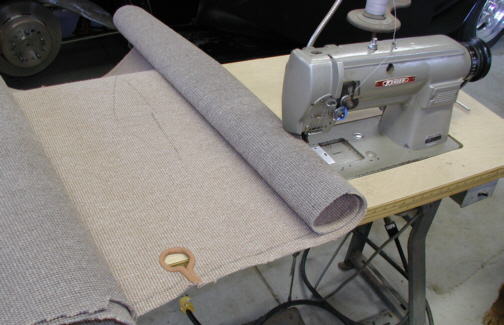

Here's the carpet which has been

marked and is almost ready to be cut out. One thing that needs to be done

before we cut right to the line is the area around the roll cage

cut-outs. My neighbor use to do upholstery awhile ago too and he still

had his sewing machine. He told me that if I ever needed it, that I could

borrow it so I took him up on his offer. This is just what we needed

so Paul started cleaning it so he could do a test piece or two. Notice

the template at the top all carefully folded.

|

|

|

After quite awhile of playing with

this machine, Paul was able to make a stitch or two. We used some scraps

of leather that I had left over and sewed them around the cut-outs for the

cage to pass through. Now this wasn't easy to do because of how large

the carpet is compared to how much room we had to work with in and

around the machine. I held the end of the rolled-up carpet and Paul did

his magic while I walked it around the table on his commands. One of the

things that was happening was the thread kept coming off one of the many

areas that it pass's through on it's way to the needle. If you look close,

you'll see some blue tape on the front of the machine that was used to

keep the thread from coming loose and it worked like a guard. Hey, whatever

works is what I say. The end result came out great and I'm very happy with

it. Once all four places were sewn, it was time to cut the carpet to the

line and see how it fit. Paul

didn't want to cut to the line right away because of how much handling

that needed to be done while it was being sewn. This way all the edges would

still be in

good shape when we finished. The diamond shaped lines that you see will

be the cut-out that goes over the tunnel. When the carpet goes up and

over the the hump, the opening will come together and butt against each

other leaving no gap at all. He ended up with this shape from the

pattern paper that was used earlier. By looking at that shape, it sure

doesn't appear that it would work, now does it?

|

|

|

Here's a close-up of Paul's handy

work. The carpet will get trimmed where the line is and then the ends

will get tucked under the panel that is next to it for a nice clean

look. You can't see the seam because it's been wrapped with leather and

then the ends get glued to the back of the carpet. The end result is a

nice clean look that doesn't even look likes it been sewn.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38 39 40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |