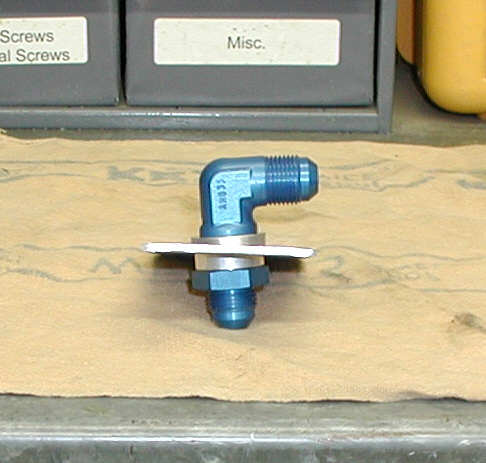

What I did was make a tapered spacer

to go between the fitting and aluminum plate. By using a 1/4" thick

piece of aluminum with the same size hole as the plate (3/4"

diameter), I sanded an 1/8" off the one side to produce a taper. I

then cut off the excess and sand it round to fit like a washer.

|

|

|

I tried using only one tapered washer

but it wouldn't tighten down very well so I made a second one so the

fitting and nut would be parallel to each other. This worked great and

now the fitting sits at the correct angle.

|

|

|

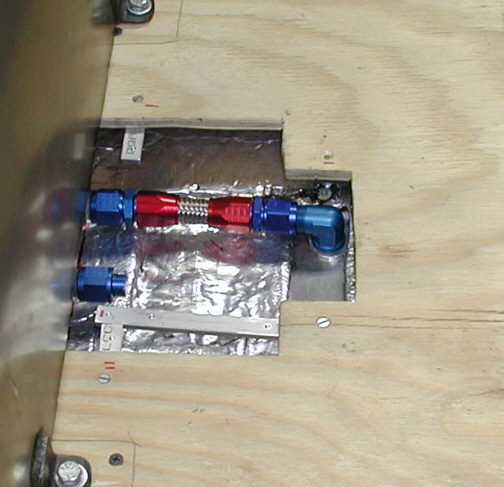

This is the 4" longer line I had

to make. I had a LOT of trouble making this piece because it had to fit

just right. The first one I made was to short....along with the second

one. What I did was make one a little too long and trimmed it down a

small amount at a time till I had the correct length. I didn't have to

make any of the lines fit as close as this one did at any other time building the

car so this was a

challenge....to say the least. The reason it had to be just the right

length is because the tank and the fitting are close to one another and

they both bolt in place. This makes the length of the line critical and

If I never have to make one like this again, it will be too soon.

|

|

|

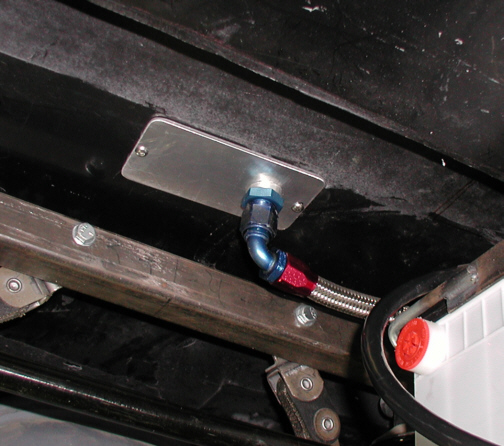

A look from the underside of the car

shows the finished plate with the fuel line connected. This plate cleans

up the hole very well and also keeps out any dirt that might find it's

way into the trunk.

|

|

|

At this point, the gas tank is finished and all that

awaits is to put fuel in it. I tested the tank with solvent to make

sure that it didn't leak because when filling it with water to do any

testing (like I did before), the water doesn't find ALL the holes like

solvent can. Solvent is thinner, like gas is so it's just a little

insurance against any leaks. Once I was satisfied that the tank was

leak-free, I rinsed it out with a little gas and then bolted it back in

place and put a couple of gallons of gas in it so I could start it. The

reason I wanted to start it was because it hadn't been run for a couple

of months so this gets things moving around which is a good thing. When

I turned the key, there wasn't even a click. I tried the dash lights and

again....nothing. I measured the amount of voltage in the battery and it

only had five volts. Well no wonder why nothing worked, the battery was

dead so out came the charger to give it new life again. I let it charge

over night and tried it again the next day and it had fire in the hole.

It sure is nice to here it run, even if it's only for a few minutes. Now I can get

busy on

my roll cage again which is one of the last things to do and the list is

getting very short at this point.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38 39 40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |