|

To make sure that both pieces were the

same, I clamped them together and then sanded them. Now that the pieces

are the right size, let's weld them in place.

|

|

|

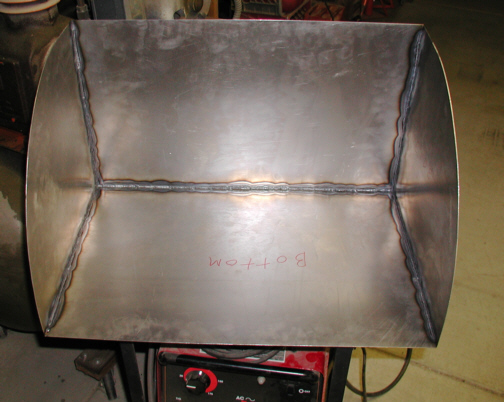

To weld this together, I first

tack-welded each end and then tacked the middle. I then put more

tack-welds in the middle of those and repeated this process till I had a

tack-weld every two inches or so. I then started welding on one end and

joined the first tack-welds together. For the next set of welds, I

skipped the next tack-weld and started on the following weld. The reason for

this is so I don't warp the thin material as easily. This seemed to work

pretty good as you can see.

|

|

|

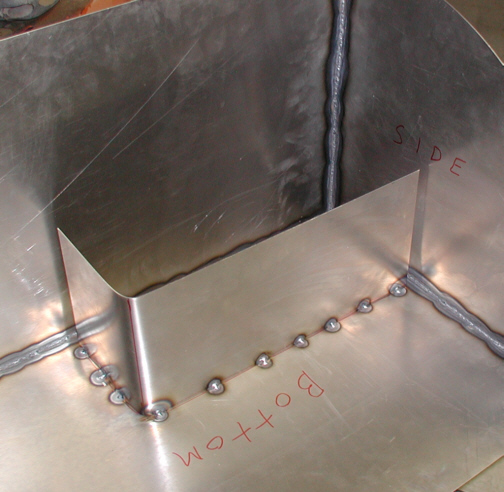

What I'm doing here is putting a baffle

in for the fuel sending unit. This will help to keep the sending unit

from bouncing around so much which will keep the fuel gage from moving

to quickly. Notice the ends aren't welded to the back or side. This is so fuel

can get inside the baffled area.

|

|

|

Now that the inside is finished, it's

time to put the top on it. The first thing I had to do was to make sure

that the top was square with the back. If it's not square, I might end

up with the top being to one side once I got to the other end and then

it wouldn't fit so this was a critical step. Once I had the back square

and tacked in place, I used an old motorcycle tie-down strap to slowly

bring the top in position while I welded. It was like a third hand

helping me which worked great. I added one to the bottom as well and

then tack welded at one inch intervals. When I had two tack welds on one

side, I turned the tank over and tack welded that side like the other

side. I repeated this process till I had the whole top tack welded

together. At this point, I was ready to fully weld the top but only did

one inch sections at a time because of how much heat was being produced.

I thought that using this thinner material would be a plus because of

the weight savings but I found out that it warps VERY easy with just the

slightest amount of heat. If I did it again, I'd use at heaver material.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38 39 40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |