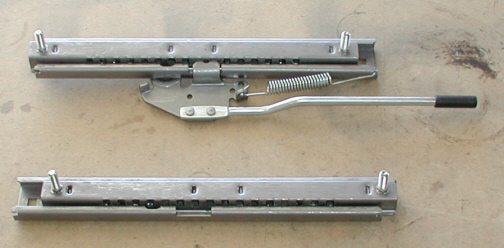

Here are the shorter ones which look

similar to the others. These tracks only adjust on one side which means

the other side just goes along for the ride. Let me know if anyone needs

a good unused set of adjustable tracks.

|

|

|

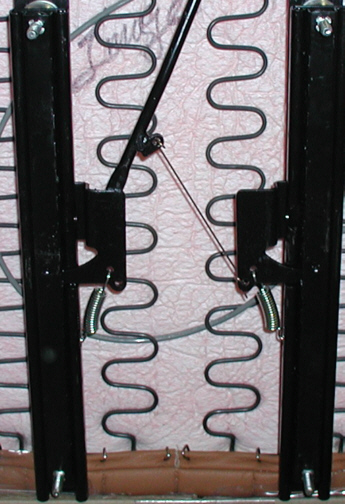

I installed a piece of welding rod to

go between the two tracks and they work great. I'll be using a larger

diameter piece of material in place of the one that you see here later

on but this was handy at the time.

|

|

|

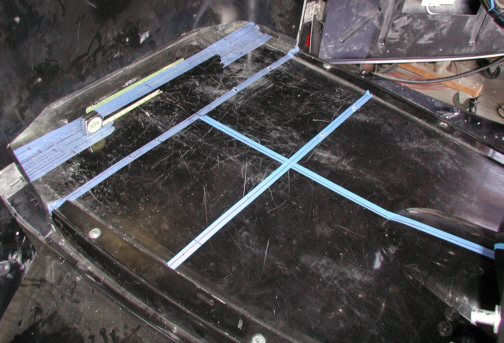

I laid out the area that the seats

were going to be at to get a better idea of where the holes had to be

drilled in the floor. The piece of tape going from front to back is the center

of the car and the two cross pieces are where the holes will be drilled.

After looking at the studs in the tracks, I remembered how thick my

floor was. The studs were just 7/8" long and my floor was 3/4"

thick where the seats were going to be mounted. That didn't leave me

enough room for a washer and nut so I had another problem to deal with.

After thinking about it for awhile, I came up with three ways that might

work. First way, cut the studs shorter and weld on a longer stud. Second

way, counter-bore the bottom of the floor (the under side) so I could

get a washer and nut on the existing studs. This second way would weaken the

floor to a point that I didn't want to deal with. Third way, make some

nuts that would work with the existing studs. Which way do you think I

went with?

|

|

|

Here is what I came up with, by

starting off with 1/2" diameter bolts that have a solid round

section below the head (the bolts were 2 1/2" long but the threads

were only 1 1/2" long), I cut off the threaded area, drilled and

tapped some 5/16-18 threads all the way through and then cut the

thickness of the heads down by a .100, I now had some nuts that I could

use. What I did at this point was drill a hole slightly larger than the

nut size (1/2") and then slid an oversize washer over the nut and

threaded them on the studs.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38 39 40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |