This is the last piece that will

finish the tank. It's a sump which is the low point of the tank and the

gas lines will hook into it. Now it's time to drill two holes and then

weld some fittings to it.

|

|

|

I'm going to use # 8 AN fittings to

run my fuel lines like the tank has. These fittings are made by

Earl's and are made out

of steel. They will be a challenge to weld because of the thickness

difference between the two.

|

|

|

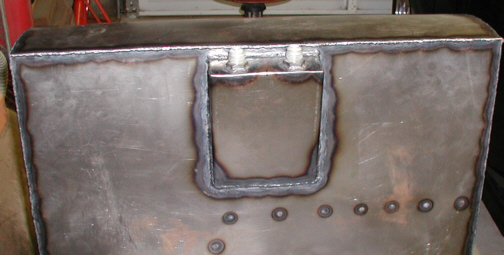

| This is where the sump will get welded

on to the bottom of the tank. I cut this opening with my Dremel and made it 2" smaller in

both directions so I would have plenty of material to weld too. Once the

sump is welded on, the fittings will stick out past the front edge of

the tank for easy hookup of the fuel lines. Now would be a good time to

tighten the rollover vent valve. |

|

|

Now that the sump has been welded on,

it's time to weld on four hold-down brackets. One thing that happened

while I was in the middle of welding the sump on was that the tank made

a loud noise and scared me. I guess the metal stretched and moved while

it was hot to the point of buckling and sounded like a bass drum which

made me jump. After my nerves had settled down, I continued welding and

it happened a second time. Now I was gun shy and decided to let the tank

cool for a few

minutes and while it was cooling, it happened a third time but not as

loud as the first. Once it cooled down completely, the bottom was much

straighter than before. I started welding again and finished without it

making me jump again. I've never had that happen to me before but

then again, I've never welded something this big out of something this

thin either.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38 39 40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |