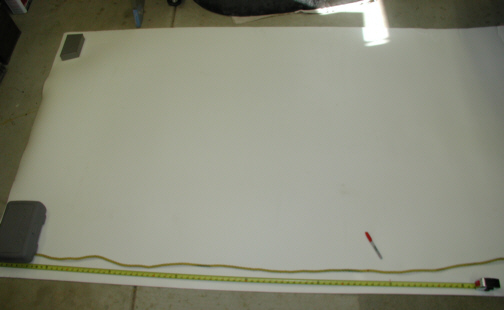

I'm getting ready to cut this foam to

length for the top rear panel but needed to know what length to cut it at

first. I used a rope

to find the dimension that I needed because of the curved surface. I

marked the rope and then laid it on the foam and added six inches to it....just because. Now the height seemed straight forward as it was 13"

but after thinking about it for a minute, I wasn't so sure. I also

needed to take into account that two pieces were going to be used from

this 60" wide chunk of foam. The other piece will be used for the

bottom portion that goes behind the seats which is taller than the one

I'm working with now. After measuring the other panel and this panel, I

had plenty of extra foam to work with so I was going to leave myself

several extra inches to play with. I cut the height at 21" just to

be safe. Why 21"? I don't know but it just seemed right at the

time.

|

|

|

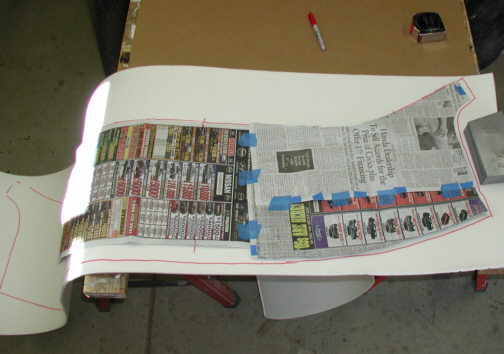

After cutting out the foam, I held it

up in it's position to see how things looked. What I mean by holding it

up in position is I'm going to install the panel where it needs to be and

then work with installed instead of making a wooden jig to do it all on. This makes things

harder because I'm inside the car but at least I know that it will fit

when I'm done. Well the foam didn't fit like I wanted because of the curved

surface. I noticed that while holding it on the straight section in the

back, then trying to bend it around one of the curved ends, it would

wrinkle so I needed to cut some foam in a couple of places, but which places?

I didn't know exactly so I

made a pattern out of newspaper and then transferred it to my foam.

Because the curves were the same on both ends, I could use my pattern on

either side by flipping it over and then tracing around it. Notice how

much room I had left over from top to bottom. After adding eight extra

inches and thinking that I'd have way more than I needed, I only had

about one and half inches to play with. I didn't take into account how

much curve that I was working with when it was laid out flat so I got lucky with this one.

|

|

|

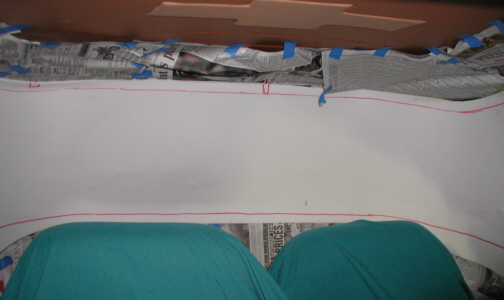

Here you can see the foam has been

glued on. I first masked off the area around the panel and covered the

seats with an old sheet before I sprayed any glue. By masking off the

area around the panel and then spraying the glue, this would keep the

right shape and contour so the foam would go on correctly. I was

thinking that if the panel wasn't setting like this, the foam would or

could have wrinkles in it. I'll be doing the same thing when it's time to

put the material on. I marked a center

point on my foam and matched it up with another mark that I put on the

paper to make sure I

started out in the right place because I didn't leave myself very much

room for any

errors. This worked out good but it's a little cramped inside doing it

this way. Now I need to feather out all the edges so it won't have such a large step between panels once there're covered with

material.

|

|

|

| 12/19/04

I sanded all the edges so the transition between

the two panels would have a closer fit. It's hard to see here but I

feathered the edge back 1 1/2" to 2" all the way around. I

left a small amount of foam around the opening for the down bars to pass

through so it will hug the tubing without any gaps because when I was

cutting out the fiberglass section around the tube, I made them just a little

large. If you notice, the window opening has been trimmed back a small

amount from the edge. I didn't plan on doing this but after placing the

panel in the car and then trying to install the window trim, it wouldn't

fit. The reason it wouldn't fit is because the foam is 1/4" thick

and now the screw holes were off by that amount so I drew a line around the

window trim and cut out that section. I feathered out the edges around

the opening like I did for the rest of the panel till the window trim

would fit. It's a good thing I tried the trim now and not after this

panel was covered.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38 39 40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |