I know this has nothing to do with the

interior but I just bought this aluminum floor-jack and had to share it.

This thing can lift 3000 pounds and it only weighs 24 pounds. It will

easy on the back when it's time to load it in my truck and it's a lower

profile than my other floor-jack too. It has polished stainless

fasteners and a one piece front wheel for easy rolling. I don't think KD

(Kevin's Dog) thinks much of it but I sure do. They were on sale at

Harbor Freight so I had to have it!!

|

|

|

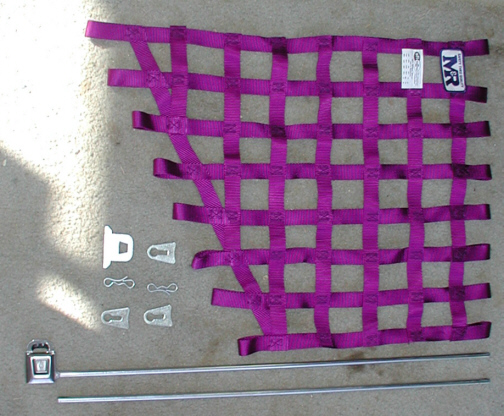

| Going back to the interior, what I'm

getting ready to do is install a window net. A window net is something

that I'll have to have to pass tech inspection when I want to run down

the track. The rule book states "a ribbon-type or SFI Spec 27.1

mesh-type window net is mandatory on any full bodied car required by the

rules to have a roll-cage. It also must be securely mounted on the

inside of roll-cage, with the permanent attachment at the bottom".

By placing the attachment points on the inside of the roll-cage, this

will put one of the mounting hardware pieces up against my leg. I'm

not in favor of having it like that but what are you gonna do. The good

news is that the only time the window net will be in the car is when

I'm at the track. The rest of the time it will be stored somewhere in

the garage.

It's made by

M

R Products like my harness is and of course, I had to have the

colors match. I had to buy this net in a special size which costs ten dollars

more but saves you a bunch of time and trouble. I also bought some

mounting hardware which is made like a seat-belt latch system.

|

|

|

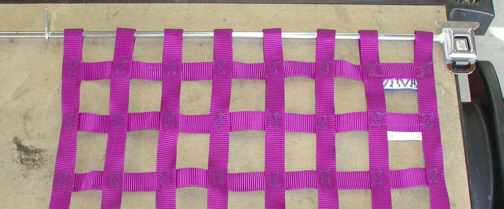

This part will be mounted on the top

of my roll-cage and have the quick release towards the front of the car.

The rod is welded to the quick release side and the other end of the rod

pass' through an eyelet. After they both get welded on, I can then trim

the length of the rod to fit better because it's way too long.

|

|

|

Here it is tack-welded in place to

make sure everything fits right first and then I can weld them in place.

I ended up with the quick release in the radius of the roof hoop a

slight amount which meant that I had to bend the rod slightly to lineup

with the eyelet on the other end. The reason for this placement is so I

would have the net far enough forward to cover the window the maximum

amount without getting in my way to much either. It's going to make it

harder to drive this way because my arm wants to rub against it but it

should pass tech. If I could have mounted the net on the "outside" of the

cage, I would have a lot more room but then it gets closer to the outside

of the car too which defeats the propose of having it. The main reason

for a window net is to avoid contact with the track surface or guardwall

in the event of a crash. Now no one wants to wreck but you have to be prepared

for one never the less.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38 39 40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |