No I didn't cut my aluminum piece in

half, this is just a test piece made out of sheet metal to see how things might look and fit. I

figure this was just a little insurance for things to come. What I did was

bend a small piece out of sheet metal to see how it would look and get

an idea of how I'm going to fasten it to the sides. The sheet metal

bends MUCH easier than the aluminum and really doesn't look to bad. The

only bad thing is that it's only .035" thick so it's not very

strong.

|

|

|

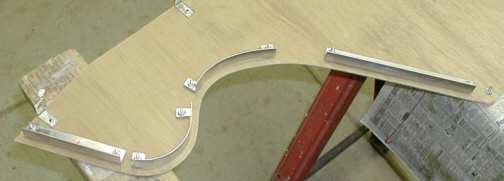

The way I'm going to attach the center

piece is with some pieces of Hook-and-Loop (Velcro). I figure if I get

enough of this stuff on the center piece, it shouldn't slip

or move. What you see below is two of the four pieces that will go on

each side. What I did was start with 3/4" X 3/4" X 1/16"

aluminum angle and cut away some of it but left enough to hold it to the

sides with screws. I also slotted the brackets so I can adjust them up

or down as needed so the top surface of the center piece lines-up with

the top of the sides. You do this kind of thing when you don't know what

your doing so you have every chance of it working.

|

|

|

This should give you a better idea of

what I'm doing. By placing these brackets in an "S" shape held

on by some 1" long 6-32 screws, I'll be sticking the Hook-and-Loop

on to these surfaces to hold down the center piece. These brackets are

3/8" from the edge which is the thickness of the aluminum center

piece + cardboard + two thickness' of material (the piece on top

and the material that gets wrapped around the opposite surface) +

Hook-and-Loop. The screws go through the wood and then I put on a

lock-washer and nut. The bracket then sits on the nut which then gets

another washer and nut on top of that. This way I could tighten the

first nut down so it wouldn't turn once the material is on. I hope this

works because I've never seen or tried this before so keep your fingers

crossed.

|

|

|

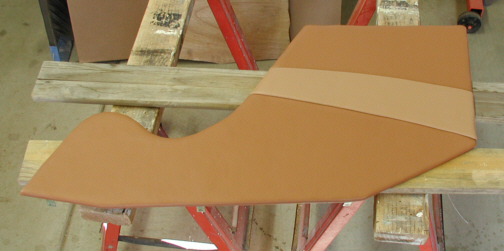

I made the console match the door and

kick panels but on a smaller scale. The lighter color isn't as wide as

the door panels because I didn't have enough material to make them exactly

like the others. I did have just enough material left over to do the

contrasting color but I had to buy more of the darker color so I'd be

able to finish the other panel. While I was buying more material, I went

ahead and bought a 1/2 hide which is more than enough but I have plans

to cover one other thing in the future. Now it's all about waiting for

the material to arrive so I can finish the other panel and see how it

all looks once it's installed.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38 39 40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |