|

Rack & Pinion Block With the minimum amount of room to work with, I'm going

to use a rack-and-pinion system to move the lock bolts. What are

lock bolts? Those are the round pins that are placed around the door

that move in and out when you rotate the handle on the outside of

the door. Some safes have them on all four sides, and some have them on

just one side of the door opposite the hinges. It just depends on the

amount of security that you're looking for, which directly affects the

cost of the safe.

What you see below is a 24" long rack that has 20 teeth per

inch (20 pitch) and a 14 1/2 degree pressure angle. The two spur gears

are the same pitch and pressure angle, has a 3/8" through hole, .900"

diameter X .750 tall and a 3/8" gear face that matches the rack. The

rack will be cut in to four pieces of unknown lengths later on.

|

|

|

|

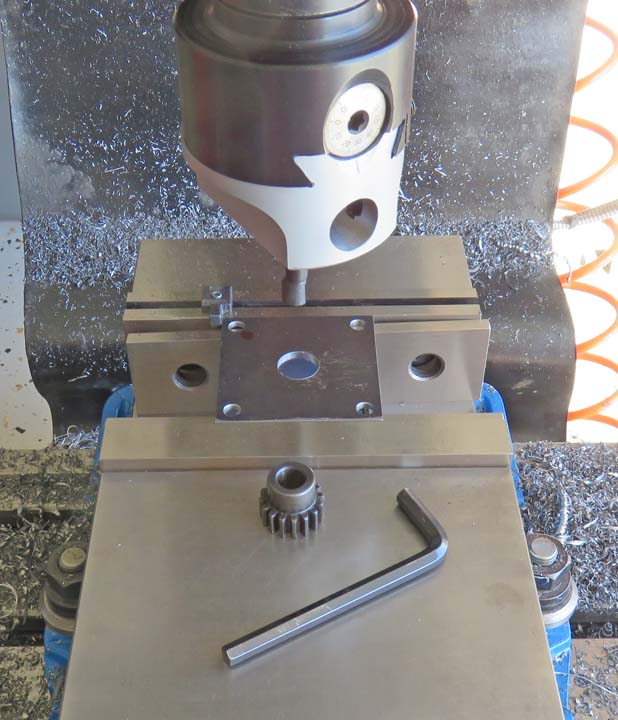

What I plan on doing is using a block that will hold the

gears and guide the racks. This block is made out of mild steel and is 2

1/2" square X .900" thick. I don't know how other safes are made but I

can see this working in my minds eye. In other words, in my head. I'll be

boring holes for the gears, cutting slots for the rack and drilling holes

for some hold-down bolts.

|

|

|

What you see below are two plates that will sandwich the

block above. These are 1/8" thick X 2 1/2" square. They will also

have bolt holes and a hole that will clear the gear in the center. I'm

machining both plates at the same time here, with them being supported by some

1" X 2" X 3" blocks.

|

|

|

|

I'll be using four 1/4-20 screws to hold the block and

plates down. The bolt holes are .250" diameter (1/4"), which means

they're won't be much slop between the screws and block. This is to make

sure the block locates in the same place and won't move. The center hole

is being bored here so it clears the smaller diameter of the gear. The

smaller diameter on the gear measures .750" so I made the clearance hole

a couple of thousandths larger. This will all make more sense later.

|

|

|

|

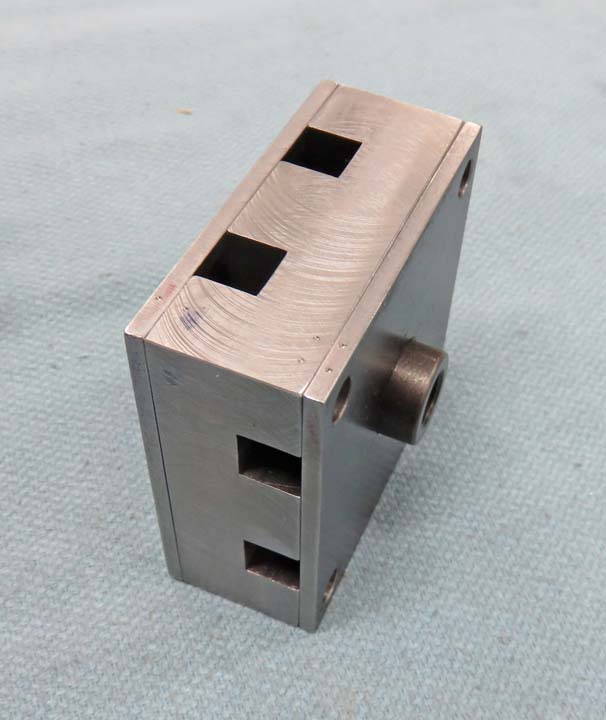

This should give you a better idea of what the block

looks like. You can also see how the slots are placed so that one gear

moves two racks.

|

|

Here is what it looks like on the inside. The gear will rest in the

center as the racks move along the slots.

|

|

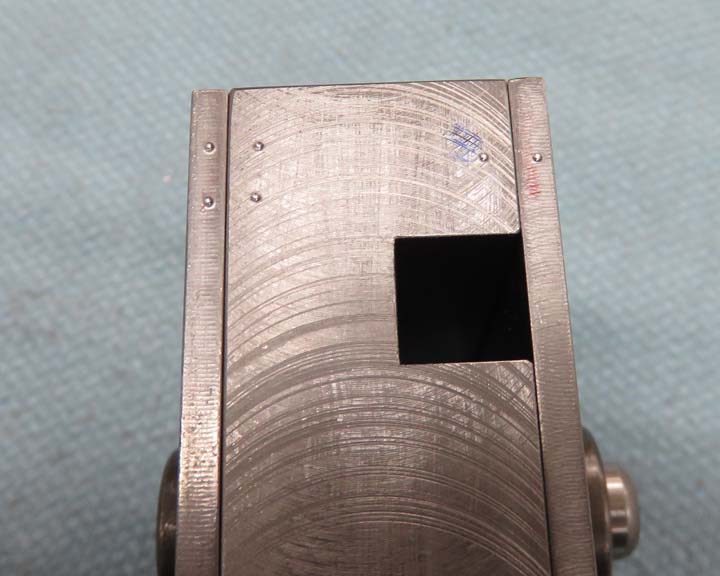

You can see how the gear sticks out enough to engage the rack, which

sits just below the surface. This way the 1/8" plate will clear the gear

teeth but will also trap the gear in place.

|

|

I made sure to mark the plates so they don't get mixed up because when

both gears are in place I want the racks to move like they're designed to.

|

|

|

Lock Bolts

The lock bolts will need to fasten to something and to

do that I'll be using some angle iron. I plan on putting two lock bolts

on each piece of angle iron for a total of eight. I'm machined all the surfaces of the

angle iron so they will be square. Below I'm cutting the top edges (two

cuts for each piece).

|

|

|

This is what it looks like with the top edges cut. The size is 1"X 1"X

5".

|

|

|

Here I'm cleaning up the top surface (two surfaces each).

|

|

|

And last I'm cleaning up the inner surfaces. This will make it easier to

work with because angle iron isn't square when you buy it.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24 |