|

I tack-welded each corner before I fully welded everything

(both sides).

This helps keep the warping down to a minimum. Once the tack welds were

in place, I put the heat to them all.

|

|

|

| Machining The Welds

Here I'm machining the welds flush with

the frame. This doesn't have to be perfect because I'll be doing a lot

of grinding and bodywork later.

|

|

|

After machining, it looks like the welds came out pretty good.

|

|

|

|

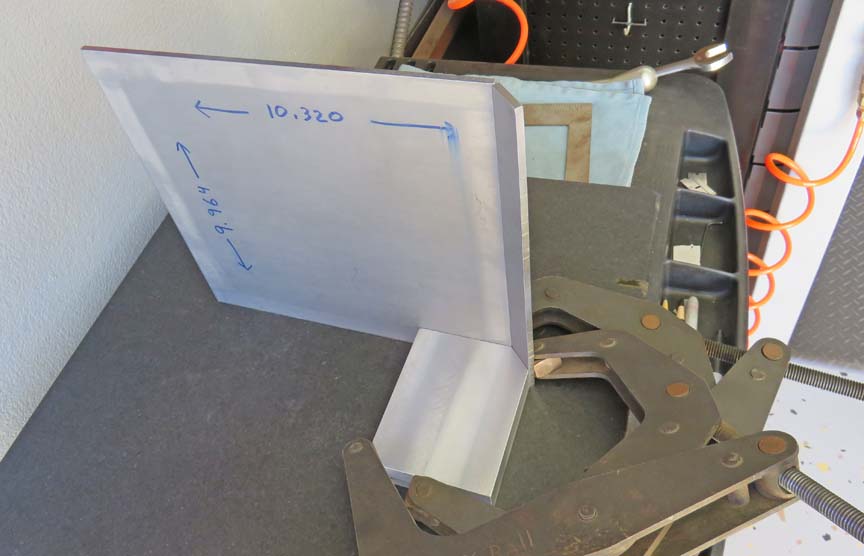

Making Tooling I'm getting ready to weld the sides together and to help

with that I'm making some tooling. I squared this block of aluminum first and now I'm

making that 45 degree angle the same length as the smaller corner

pieces.

|

|

|

This block is going to be a welding fixture to help keep one large side and

one angled piece in the right position. The second 45 on the other end is

for clamping on.

|

|

|

So I don't get confused.

|

|

|

|

Tack Welding The Sides Together

I'm using my surface plate to setup on because it's very flat. And with

all the pieces getting welded that are already square, this makes sure I get the

two pieces in the right place.

|

|

|

|

That fixture worked pretty good and now I have all the

sides tack welded. This was the easy part, fully welding them is much

harder because I'll have to deal with heat related issues.

|

|

|

|

Here I'm welding the sides together. Now this turned out

to be a challenge, much more than I thought. To keep everything square,

I'm using a nice flat steel plate to rest my pieces on. However, that

flat piece isn't very big.

|

|

|

|

I ran out of real estate on that smaller steel plate so I had

to use my surface plate. This worked great but I had some trouble

getting the last piece nice and square. But to be honest, I never really

did get every piece perfectly square, but I got pretty close.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24 |