|

A Change Of Plans I took the four pieces to my work and I cut them on the

bandsaw. One of these days I'll have to buy a bandsaw because they work

great. Anyways, it's time to machine the four smaller pieces along with

the one edge of the larger ones with the saw cut.

|

|

|

|

I noticed that all the pieces now had a bow in them once

I cut them. This was no surprise because the steel company sheared them

all, which puts some stress into the material right where it was cut (or

sheared). What you see below is my work piece sitting on my surface

plate and a 1/16" shim that just fits under it. This will need to be

addressed.

|

|

|

|

To remove the bow in the material, I'm using my milling

machine work vise to help me straighten them. With two round pins

at each end and a small block in the center, I can tighten

the vise to bend my work piece. This worked pretty good but my only

complaint is the work pieces are much longer than my vise is. This means

I had to move my work piece from side-to-side on some of them.

|

|

|

|

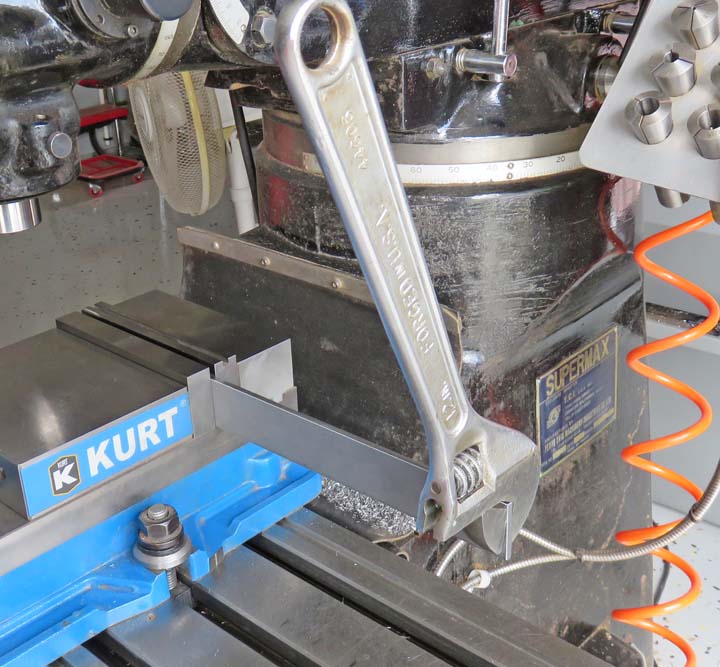

Once I had them straightened, they now had a twist in

them. No big deal as I used my vise to hold them and my 'many

sixteenths' (Crescent wrench) as a lever to twist them with. This worked

great so now we're back in business.

|

|

|

|

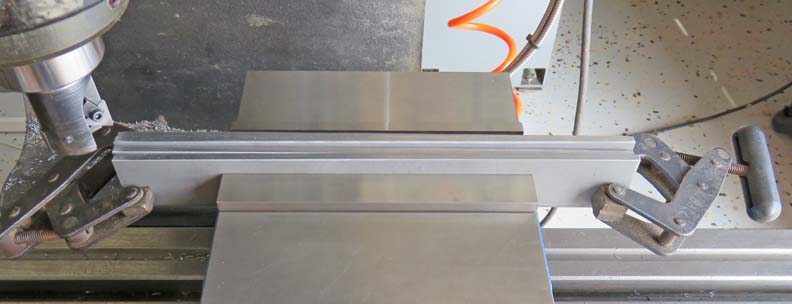

I'm getting ready to machine them all at the same time,

because they will all be the same size. With the vise being six inches

wide and my work piece being 12", I used some clamps at each end to help

keep all the pieces together. With all the pieces being held together

this way, this helps keep everything much more ridged, like if it was one piece.

|

|

|

|

I'm machining the ends that I made the saw cut from, making sure to keep everything square as I go. Yes, this was a

little extra work, but I think it will be worth it in the end.

|

|

|

|

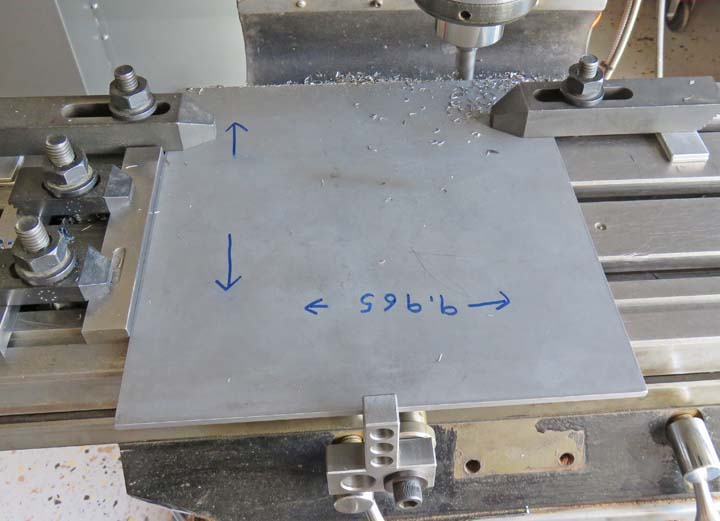

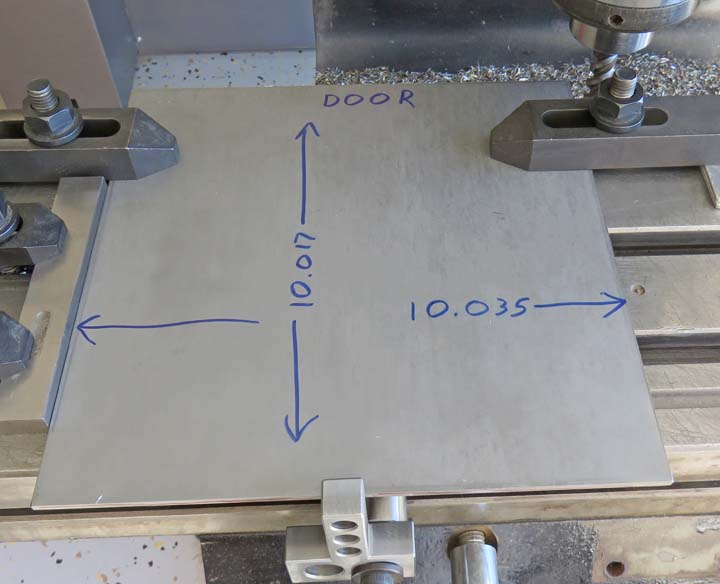

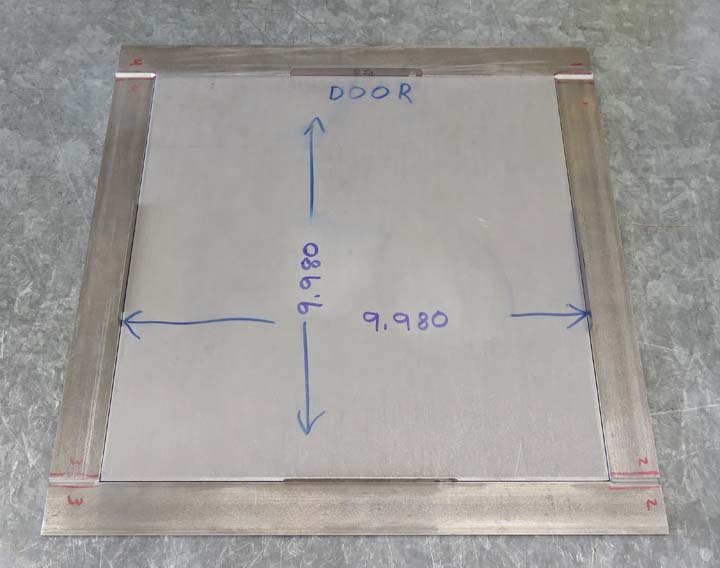

Here I'm machining the door, which will end up at 9.980"

square (just under 10"). The sizes that you see on my work piece is how

I received them and this odd size that I ended up with is what it took to make them square.

|

|

|

|

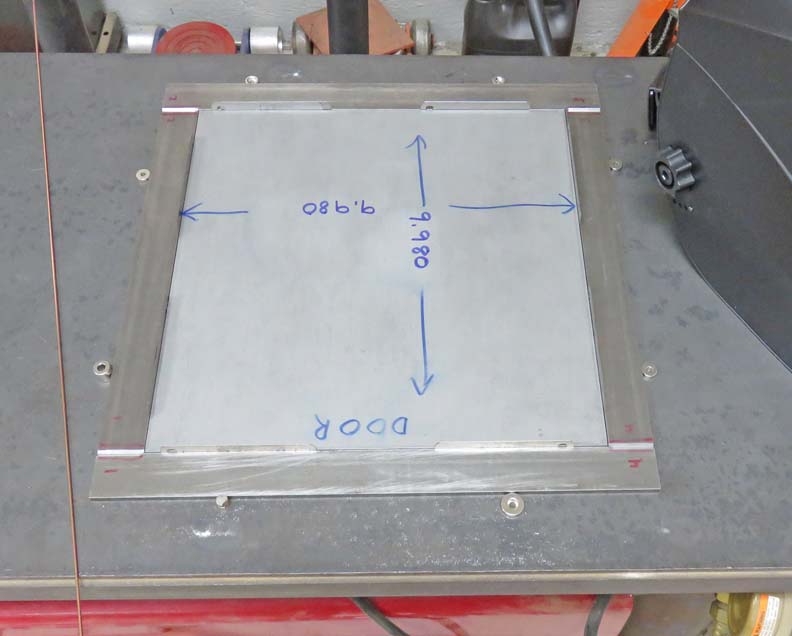

Time To Do Some Welding Now that my door is nice and square, I'll be using it to

help weld the door frame together. This will work much better than if I

tried to measure it from corner-to-corner trying to get it square. Also

notice I have shims between the door and frame.

|

|

|

|

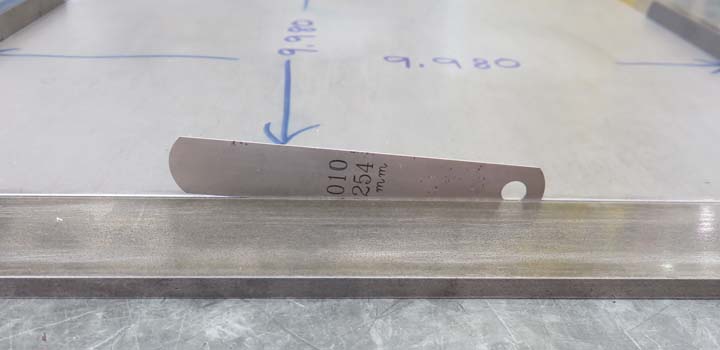

I used .010" shims on each side, for a total of .020"

clearance between the door and frame. I don't think this will be enough

clearance when I'm finished, but I can take more off later by milling

the sides of the door if need be.

|

|

|

|

My welding table is steel so I used some small magnets on

all the sides to help keep everything together. I also added

twice the amount of shims before welding (two per side) because it was hard to keep

everything in the right position.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24 |