Component Parts

I'm going to

need a lot of different parts to make all those gears work together so

while they're out getting plated, this will give me some time to work on

other things. Most of the parts I'll be making will be out of aluminum,

mostly for weight reasons because once everything is together it's going

to be very heavy.

What you see below is a block to hold a shaft (right)

and a thin trim piece. The block measures 2 3/4" X 1 3/4" X 3/4". I drilled

and tapped two 5/16-18 threaded holes to hold it to the plywood and plan

on using .500 (1/2) steel shaft material that will press-fit into this

block. However I don't have the shaft material yet so I drilled the holes

undersize at 7/16" for now. Once I have the shaft

material I can measure it and machine my holes accordingly.

The trim piece that you see will be used on the front

side and will do two things: first it will clean up the area where the shaft

comes through the plywood and second, it will distribute the load of the

bolts to hold the blocks in place. This trim piece is 2

1/2" square X .090" thick and the center hole is 9/16" diameter.

|

|

|

Here are all the blocks and trim pieces. I made a couple

extra just in case something goes wrong. The two blocks on

the right are going to have bearings in them which I'll talk about

soon.

|

|

|

A few days later I bought some shaft material and there are two types:

the

top one has a keyway that runs the entire length (arrows). The

bottom one has no keyway and is easy to tell the difference because it's

black oxide coated. By the way, this coating has a mild rust

preventative and is easy to work with.

The shaft with the keyway has a diameter of .499" and

the other shaft (black) measures in a .4995". I bought one foot of each to do

testing with and if they work then I'll by more later. I also did some

research on different shaft material and a few different companies that

sell them. Amazon has just about everything so this seemed like a

logical place to start. But I quickly found out they didn't have a very

good explanation about some of their products. Don't get me wrong they

have shaft material along with a bunch of other related items, however I

needed more information about each product so I looked elsewhere.

The next place I went to was

McMaster Carr and they

had just what I was looking for. As a matter of fact, I bought just

about everything I needed for this project from McMaster Carr (except

all the pieces that I'll be making). This company has a fantastic

website and is very easy to navigate and search. Once you find your

product they have all kinds of information about it along with many

different types of CAD drawings in case you need those as well. With the

shaft material picked out I was now ready to start testing.

|

|

|

The first thing I did was cut off a one inch piece from each

bar, which was done with my hacksaw on my work bench. Once I started sawing I

knew I had some decent material because it took awhile. Next I took a

clean-up cut off each end and then took them to my work to check the

hardness.

Hardness: The numbers on each piece represents the hardness on the

Rockwell C scale. And if you're not familiar with this scale, it's the

industry standard for checking hardness of steels. In case you were

wondering, softer metals like aluminum are checked on a different scale.

Both of these shafts are the perfect hardness as I can

still drill and tap or machine them without any problems but should be

hard enough to have good wear properties. This information was on

McMaster's website but I just wanted to make sure it matched up. And

Amazon's website neglected to have any of this info which is why I looked

elsewhere.

|

|

|

After drawing some sketches and doing some calculating,

I came up with a length which will be 3.350" long. Note that I chamfered one

end and the other is just deburred. The chamfered end is to aid the gear

being placed onto the shaft. Now this got me

thinking, how am I going to keep each gear from coming back off once

they are in motion? To make sure they don't move too far inward I can

make some kind of a bushing or spacer but how about the other?

|

|

|

This is what I came up with to keep the gears from

coming back off, a Ball Plunger. Ball plungers have a spring inside the

body that presses against a ball at the end. In my case the ball is made from

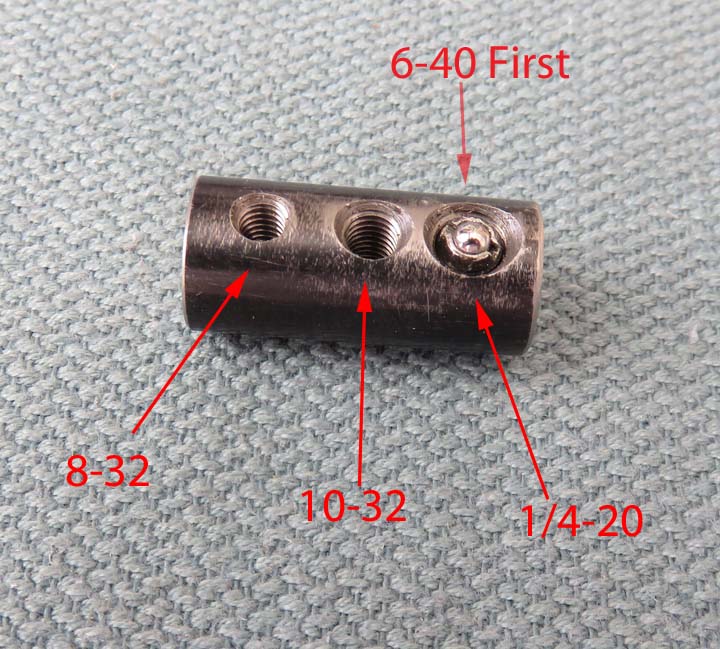

stainless steel but they have other materials as well. I bought four different thread sizes

and each one has a different spring rate. The smaller the thread size the lighter

the spring rate. This makes sense because they can only package so much

spring in each size ball plunger.

The sizes I bought are: 6-40, 8-32, 10-30 and 1/4-20.

Those numbers are the thread sizes and start out small and get larger.

The plan is to test each one to determine which one works best.

|

|

|

Here is my one inch test piece of plane shaft again and

as you can see it has three different size threads in it. I tried the

6-40 ball plunger first and there just wasn't enough spring pressure.

Side note: there was only one choice for this smaller one, .5 to 1 pound spring rate.

Spring Facts: The reason there are two pound

ratings is because the

farther the ball is depressed, the more spring pressure it exerts. This

is true with any spring.

Second try: I tried the 8-32 size which had a spring rate of

.5 to 1.3 lbs. It was better but still not enough, at least not for me

that is.

Third try: I tried the 10-32 size with a spring rate of 2 to 5

lbs. This was much better and might be just what I was looking for.

Last I drilled out the 6-40 thread and tapped it with

1/4-20 threads. I bought two different spring rates with this larger size:

3 to 7 lbs. and 4 to 12 lbs. I was very optimistic with these heavier

spring rates and they didn't disappoint either. However these larger

ones had one drawback, they were longer than the others and stuck out

the other side of the shaft once I had them adjusted.

|

|

|

To remedy the length problem, I sanded the back to shorten it which

worked out fine. On the other hand this created another problem. You

see, the backs of all these ball plungers have a standard screwdriver

slot to screw them in with. But once it was sanded the slot was gone.

|

|

|

Here is what the ball plunger looks like with it in the

correct position. The 1/4-20 thread size with the 3 to 7 pound rating

seemed to work well (in the picture below). The heavier spring rate, 4

to 12 lbs. was just a little too much because it was much harder to

slide the gear over it. So how am I going to screw this ball plunger in

without a screwdriver slot?

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23 |