|

Machining The Gears Continued

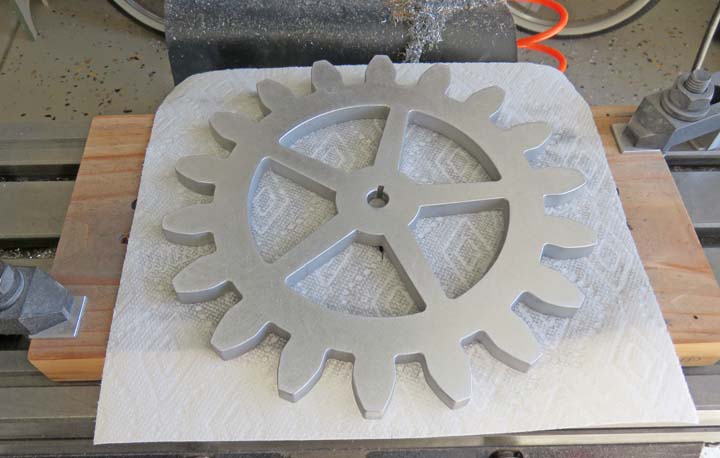

Note the wood tooling has been turned 90 degrees once again. The

reason: as the gears have gotten progressively larger, I ran out of real estate

for my clamps. By hanging some of the wood over the back of the table, I

was able to use a third clamp to help hold the larger gears. BTW, this

is the 12" gear.

|

|

|

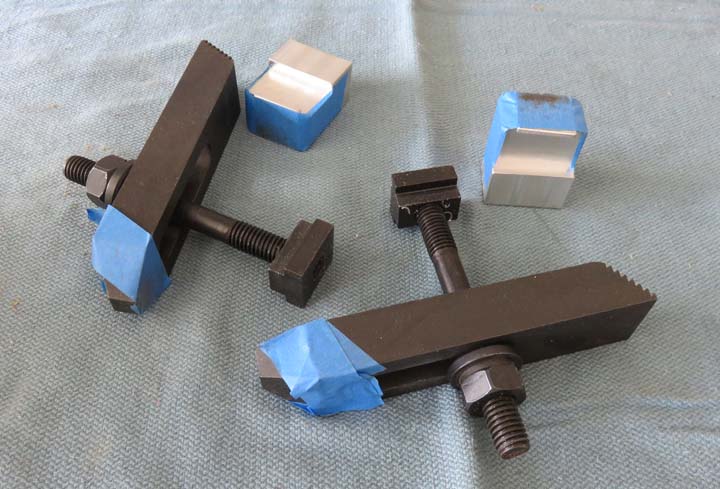

A keen eye may have noticed that I'm not using paper

between the clamps and parts any longer. The paper worked great, but it

was very slow to work with so I switched to using tape on the clamps and

blocks. I wrapped the tape around the clamps two times to make sure

everything was protected well, which worked out great. Total time for

reaming was about one and a half hours.

|

|

|

Now that all the holes are reamed to size, it's time to

chamfer both sides of them. Here are two single flute chamfer

tools, both being the same diameter but I ground a flat on one so I could

use it with my wood fixture. Now normally I wouldn't have to do this but

this is a special setup.

|

|

|

|

First I drilled and reamed a new hole in the wood tooling so I could use a 1/2" dowel pin for

locating. I also left the pin sticking out a third of

the gears thickness. By using a short pin this way, I can place the gear

over it (which will stay in place the whole time) and then chamfer all

the holes. This keeps the work piece centered while I'm working.

Now I could have used a three flute countersink for this

and not used any clamps at all. However, that method can cause the

countersink to chatter and I didn't want that either. And to make sure there

isn't any chatter, you need to clamp your part down, which is what I

did.

|

|

|

Here you can see what I came up with which worked out great. And using a

single flute countersink makes a nice finish. If you don't clamp your

work down using a single flute countersink, the part will 'walk' or move

around as the tool makes contact so clamping is a must.

|

|

|

|

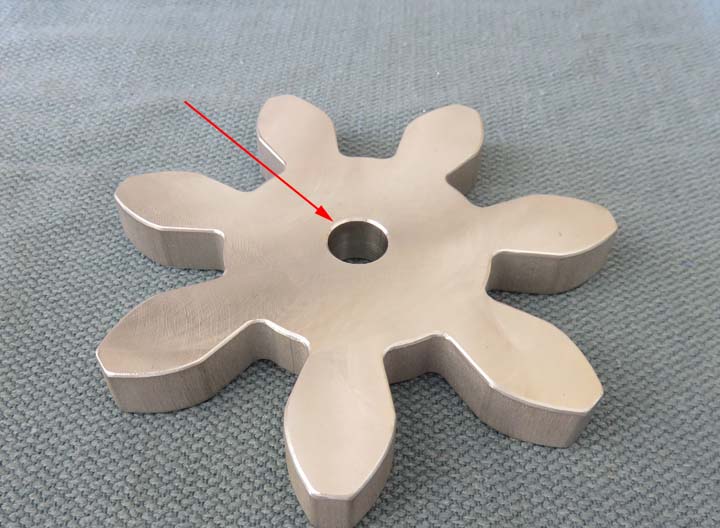

Here is a finished chamfer and they came out great. The

size is .025 thousandths of an inch which should work out pretty good.

The hardest part about this operation is changing clamps because

chamfering takes only seconds. Total time for this operation was about

one hour.

|

|

|

|

Now that all the machining is done, I wanted to remove all the cutter

marks so it was time to sand. I bought this orbital sander made by

Makita just for this job. The 5" sanding discs attach via hook-and-loop

and the sander has a variable speed motor so you can adjust it to

whatever you want.

I used my handy wood tooling once again to keep the work piece from

moving, although it did spin a small amount on the pin. This setup

worked out really well and made it pleasant to sand each piece.

|

|

|

I used a paper towel for the finish sanding because the wood tooling had

gotten very dirty from the machining and rough sanding operations. And

all this dirt and grime would transfer onto the surface of the gear

making it look bad. I could sand both sides of four to six gears before

I had to use another clean paper towel. This worked out great and it was

very

easy.

|

|

|

As you can see this made a big difference. The sanded part is on the

left and all the machine marks have been removed now. I used two

different grits of paper, 80 to rough them and 120 to finish with.

|

|

|

|

Here are all the gears finish sanded and at this point are ready for

plating. Total time for sanding was about three hours. Speaking of

plating, I mentioned the hole diameters being reamed oversize awhile

back (.503) and now would be a good time to tell you why. I'll be using

1/2" (.500) diameter shaft material for these gears and with the plating

build-up at .001 per side (one thousandth going into the material and

one thousandth build-up to the outside of the material) I should end up

with my hole diameters at .501" when they come back from anodize. This

will give me the perfect slip-fit of about .001" between the shaft and hole, at least

that's the plan.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23 |