|

Building A Box Continued

And there you go. Now I realize this isn't a normal

operation that a carpenter might do but then again I'm not a carpenter

either. I just do what I think will work and go from there.

|

|

I wanted to make sure this stayed where I

put it because this box is heavy. I used some 2" X 4"s to help support

it and it came out really solid.

|

|

|

Here you can see all the recessed bolts and yes....I

placed one every foot because I wanted to make sure it stays put. Again

this surface will sit against the wall and will probably need some extra

nailing blocks when the times comes to mount it.

|

|

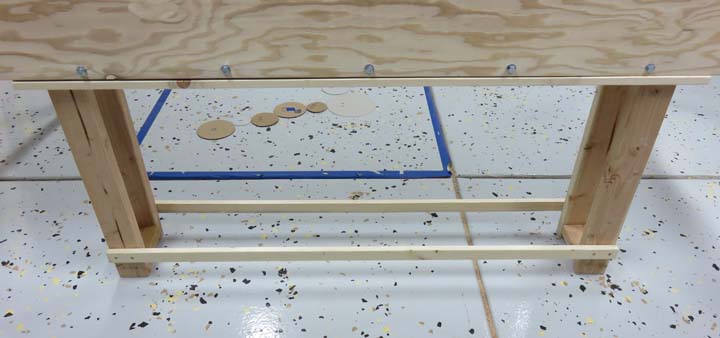

I made this stand out of 1" X 10" pine and attached 2" X 4"s as legs.

The box sits two feet off the ground, which seems like the perfect

height and might be what the kids will end up wanting too.

|

|

By adding the stringers to the bottom really made this stand stable. And

with those supports on the sides it hardly moves at all which makes it

nice and safe.

|

|

|

Mounting The Hardware Now

that I have the box built, it's time to start mounting all the pieces I

made. I started in the lower right hand corner, which will be the gear

that will have the hand crank and worked my way from there. I used my

life size

floor model to aid me in getting the location for each gear.

This worked pretty good and it went smooth.

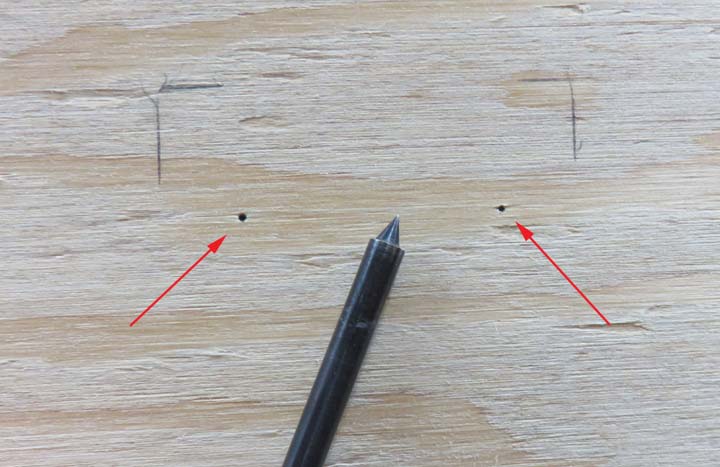

To mount each block I'll be doing the same thing I showed you earlier. I placed the block over the spot I measured

from my floor model, leveled the

block and then used a pencil to mark the top corners. Then I used my

transfer punch placed through the threaded holes and tapped it lightly

with a hammer.

|

|

This is what it looks like when I removed the block. The small dots are

where I'll need to drill but I'll also need to find the center for the

clearance hole for the shaft to pass through.

|

|

|

I'm using a 1/8" drill as a pilot hole before going to

full size. The reason for this it two fold: first it's easier to keep

the drill in the right location because it's very easy to find the small

center punch. And two, the larger drill will want to follow this smaller hole

putting it where you want it compared to using a full size drill first, which

tends to walk or follow the grain of the wood when using a hand drill.

|

|

Once the holes were drilled I set the depth of the shaft collar using my

calipers. These collars work great and hold very well.

|

|

I used the trim plate to measure from and placed all of the collars

within .010" (less than 1/16 of an inch).

|

|

|

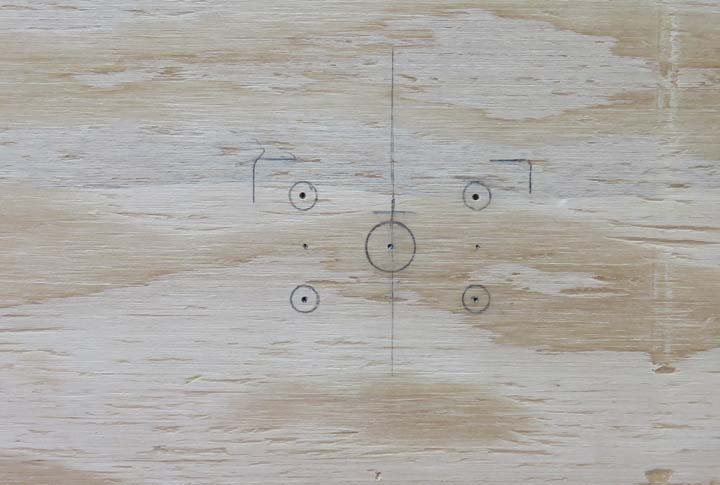

The blocks with the bearings all have four bolts and the

one that I'm working with here has a gear and a sprocket. Notice the center line running

vertical and the horizontal line that is slightly above the center

circle. This was the location that I got from my life size floor model,

which ended up very close to the actual location that I used. The reason

there is a difference is because of the chains length being slightly

different than my string on the floor.

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23 |