|

Machining Continued

After cutting the shaft to length I needed a way to

attach the two together. What I came up with was a 'roll pin' that will

pass through both pieces. The pin is 1/8" diameter X .700" long which

will work great for this application. If I ever need to separate the

two, I'll just tap out the pin with a punch and hammer.

|

|

|

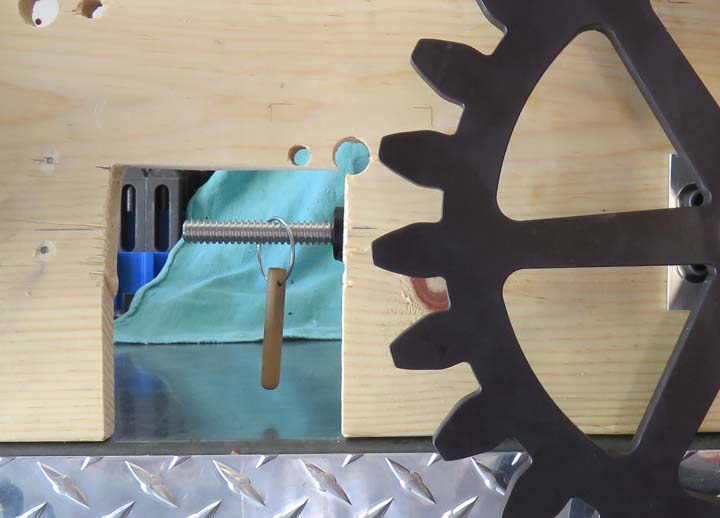

To line up both pieces, I'm using a 1/8" dowel pin that

was inserted from the bottom side. The roll pin however is a press-fit

and trying to line up both pieces once you start hammering makes it

tough. By using this second pin the holes are aligned while you hammer

the pin in and it moves the other out of the way with every hit.

|

|

Here are the two pieces pinned together and ready for action. Now it's

time to reassemble the gearbox and see how it works.

|

|

This is a mockup of the ring hanging from the threads and is basically

what the people will see when it's being dispensed. So far it works just

like I planned!!

|

|

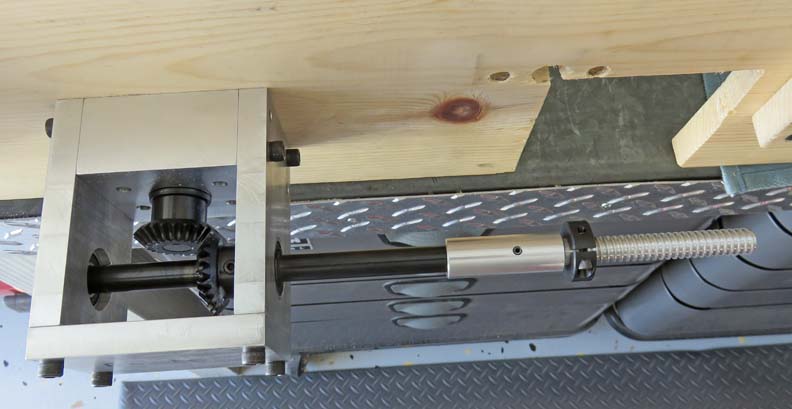

A look from the back side. The shaft and threaded piece run very true

and should work pretty good.

|

|

|

Here is a close-up of the groove (arrow) which is a

where I started my threads. Once I engage the feed lever on my lathe

to thread, the tool moves and the threads are cut. However while I'm waiting

for the threading dial to be in the right position before it's engaged,

this groove is produced.

|

|

And by using a shaft collar I've covered the groove so there's no chance

of the ring ending up in the wrong place. An easy and simple fix!!

|

|

|

Making Changes

Matt and Angela came over for dinner one evening and I

was able to show them my progress. One thing they would like to have

changed were these trim plates. What they wanted is for them to be

round, not square, so I told them I'd make that happen.

I used a paint can and drew a pencil line around it to

represent what they might look like. They both liked it so now I'll be

turning them all round.

|

|

|

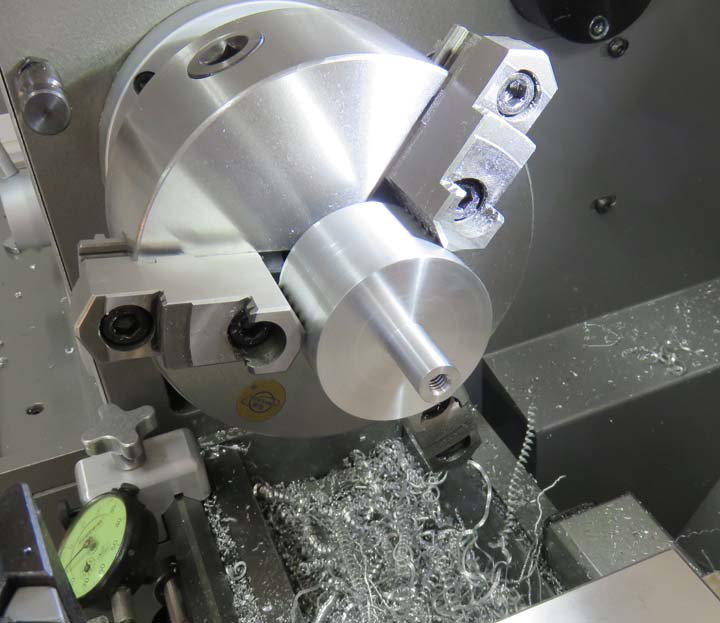

In order to turn these plates round I'll need a fixture

to hold them. What I did was start with a 3" diameter piece of aluminum

and made a spud to fit the center hole. This fixture will hold 11 parts

at a time.

|

|

|

When turning square parts (that end up being round)

this is what's called an 'interrupted cut'. An interrupted cut is prone

to spinning your parts while being cut so I drilled and reamed some 1/4" holes

for dowel pins. These pins will go through one of the bolt holes and

will be used to 'drive' the plates while they're getting turned.

Notice I have two lengths of pins here, the long one is

for the trim plates with two holes and the short one is for the trim

plate with four holes. The short pin is for the three trim

plates.

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23 |