33 Coupe Paint 29

11/05/05

Both door panels are now on the car

and fixed. I like the color of the leather against the orange. I

wondered how it was going to look when I ordered it and envisioned it a

bunch of times in my mind before I actually had it in place. If it didn't go well

together at this point, I'd be out of luck or start the interior over. The

flash washed out the color of the leather a little but when your in some

natural lighting, it sure does look good together. I also finished

polishing the speaker grills which took awhile to do, but was worth it.

I like how the polished aluminum from the door handles, door pulls and

speaker grills look against the leather. There are a few more

polished aluminum and chromed items on the inside which complements the

ones here.

|

|

|

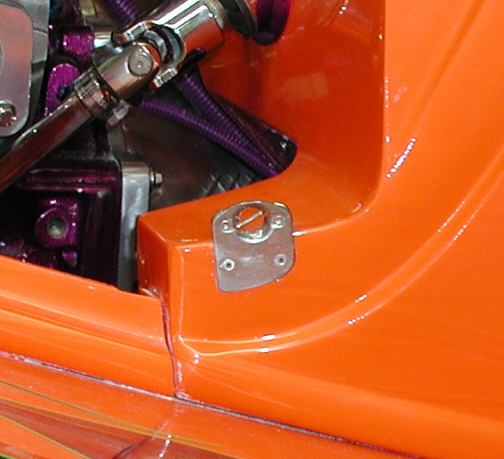

| When I installed my three-piece hood

awhile ago,

I wanted to make it easy to remove the hood sides so I could run without

them if I ever wanted too.

As you know, I used Dzus fasteners to make that happen which works

great. But the one thing I didn't think about at that time I was installing

them was the material they were made of. If I had bought stainless

fasteners, I could rest easy but I ended up with steel ones. What does

all that mean? It means that these steel ones are going to rust and now looking at them after Bart had wet sanded the car, they already

started too.

What I decided to do was take them off and chrome

plate them. This will make them look better and prevent them from

rusting. First thing to do is drill out the rivets that hold them to the body.

|

|

|

| One of the things that would happen

after I chrome plate these Dzus fastener plates is that the springs will end

up being brittle and probably break later on. Why would they break? Well

the steel plates would be fine but the springs have been heat treated and

anything over 35 on the Rockwell "C" hardness scale risks being weaker

after the chrome process. To prevent that from happening, you can have your chrome plate guy to do a process called "Hydrogen

Embrittlement Relief". This is a bake process that happens right

after the chrome plate has been applied. I won't go into the whole

process here as that's a subject all it's own.

What I'm going to do is remove the springs (heat

treated piece) for this reason and for one other. The second reason is so it

will be easier for the chrome plate guys to polish the back side of the

plates with the spring out of the way. I started experimenting with reattaching the spring

on another piece before I did the ones that came off the car. What I came up

with is to first drill the heads of the rivets that hold the springs out

to remove them. The next step was to find a way to reattach them so they

looked decent.

|

|

|

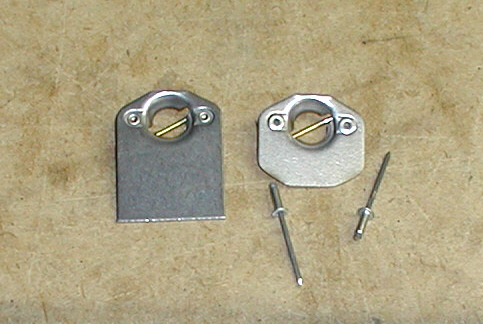

The plate on the left is an unaltered

one and is how I received them. Notice the different rivets in the one

of the right. This is what it will look like once I reattach the

springs. I used 1/8" steel rivets that have been plated so they

won't rust. The original rivets sit in a recessed area with room to

spare and my rivets fit in that same area, with no room to spare. What I

don't want is it to have my rivets stick out past the surface of the

plates because my other panel (in this case it would be my hood sides)

would be held to far away and not lineup correctly. The other piece that

holds the fasteners together has a "working length" that it

can't exceed so if anything is sticking out past the plates surface,

this system won't work right. I thought about using some small screws

here but they would stick out too far. I also thought about using flat

head screws but changed my mind.

|

|

|

To make sure the springs stay on, I used some small

washers as a backup for the rivets. Using washers on the back of rivets is

a common practice depending on what your fastening together and it my

case, it should work pretty good. The type of rivets that originally came

with the Dzus fasteners are a little different than what I'm using but

mine should do the trick. One other thing that's nice about rivets is they

don't rattle loose very easy. If I were to use screws in place of the

rivets, I might end up having them come loose. Now that I know how to put

the springs back on, I'm ready to send the plates to the guy with the

chrome. By the time I get these pieces back, I hope too have more body

panels bolted up so cross your fingers for that to happen.

|

|

|

|

1

2 3

4 5

6 7

8 9

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

|

|

30

31 32

33 34

35

|

|