I've been trying to keep busy while

I'm waiting for more body panels to arrive from my painter so I started

polishing my sill plates. I made these awhile ago out of aluminum so I

thought they would look nicer if they had a shine too them. They had a

few scratches so I sanded them with some 320 grit paper and then fed them to my buffing wheel. As you can see, there's a big difference

between them now.

|

|

|

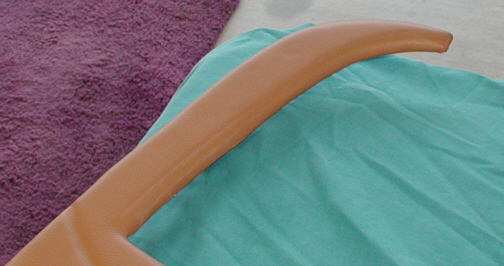

Here you can see what it looks like

now that it's installed. I used five brass flathead screws to hold them in

place and it sure does look nice against the carpet and orange paint.

|

|

|

What you see here is the upper section

to my door panel. Notice the line that my garnish molding (the trim

piece that goes around the windows) left in the leather. What I'm

getting ready to do is remove the leather from this area and sand down

the foam that's underneath it to gain more clearance between the two.

The reason for this is because the garnish molding doesn't fit right.

What I did awhile ago was remove some material from the back of the

garnish molding so it would fit better. Once I had done that and

everything fit correctly, the wall thickness ended up so thin that it

cracked while installing it. Now the molding needs to be fixed and that

means a small amount of material needs to added to it. Once that's been

done, I'll end up with even less room so this is a way to gain some much

needed space.

|

|

|

| I peeled back the leather (which

wasn't easy) and sanded the foam at an angle down to the fiberglass that

the foam is bonded too. The foam is 1/4" thick so this should give me the

added clearance that I need and once the garnish molding is installed, I

shouldn't have a problem anymore.

To apply the glue, I used a brush so I

could put it only where I wanted it because the spray can doesn't exactly

have a very precise spray pattern. I've had the spray can pointed right

at what I wanted to spray before and it's gone everywhere but where I

wanted too. Brushing didn't take but a few minutes and was applied right

where I wanted/needed it.

|

|

|

|

1

2 3

4 5

6 7

8 9

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

|

|

30

31 32

33 34

35

|