|

Now all I need to do is cut to the red

line. Along the way I will check my progress to make sure I don't go to

far. You can always take more off.

|

|

|

Here is one of the ports finished.

Notice how much difference there is between the two. I used an air tool and a carbide

burr with a rounded tip to do the work. It doesn't take long to remove

the material because it's soft. The key here is to check your work

often.

|

|

|

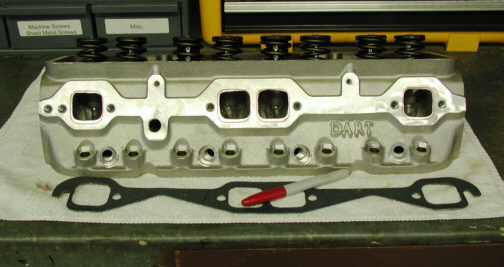

Now that I'm finished porting, I

wanted to see how much material was needed to be removed from the

adapters. Notice how much difference there is between the adapter plate

and port size. The

adapters will have to be machined but not till I get the headers to make

sure I don't take out to much material, so these will have to wait.

|

|

|

Lot's of chips were on the ground when

I was finished. It's hard to believe that all this was removed by just a

little grinding. Speaking of grinding, I still have more to do and that

means taking the all the valves out. Then I can blend the combustion

chambers and bowls (behind the valves). Stay tuned for that action

soon.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

26 27

28 29 |

|

30

31 32

33 34

35 36

37 38 39

40 41

42 43

44 45

46 47

48 49

50 51

52 53

54

55 |

|

56 57

58 59

60 61

62 63 |