Now that the timing gears are done, it's

was time to check the clearance between the connecting rods and camshaft.

This isn't a normal thing to check when doing a normal engine (one that

isn't stroked) but because I have a large cam and a longer stoke, I need

to make sure I have room. The distance between the two should be

.050" (just less than 1/16"). Using feeler-gages is a good way

to check this but I had to hold them in some needle-nose vise-grips to

be able to reach the tight areas. The only way I could measure this

was by sticking the gage through the opposite side cylinder bore and

then checking it. The sizes were .010 - .020 - .025 - .030 - .035 and by

putting a combination of any two, I could check my way up to

.050".

|

|

|

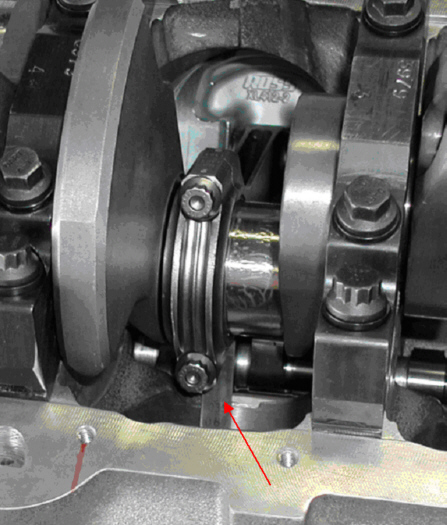

The first gage I tried was a

.035". If you look close you can see the feeler-gage between

the rod and cam below (arrow). This size wasn't even close to working which

meant I had some grinding to do on the rods. I had to go down to a

.015" gage to have it go between the two. I used a red felt marker

to mark the rod and slid the feeler-gage between the cam and rod. Then I

rotated the crankshaft back and forth while the feeler-gage hit. This

way I could see where I needed to remove material on the rod as it

scraped the red off.

|

|

|

It's hard to see in this picture but

there is a witness mark that has been scraped off so I know where the

area I need to grind is. Now I didn't want to grind ANY material off the

rods because this is the most stressed piece (next to the bolts that

hold them on) in the whole engine. That means that any material that

comes off here, weakens the rods that much more. I went very slow to

make sure I didn't go farther than absolutely necessary.

|

|

|

|

Now it was time to do some grinding so

I wrapped a rag around the piston to keep it clean. It was either this

way or put them in the solvent tank again.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

26 27

28 29 |

|

30

31 32

33 34

35 36

37 38 39

40 41

42 43

44 45

46 47

48 49

50 51

52 53

54

55 |

|

56 57

58 59

60 61

62 63 |