33 Coupe Engine 40

6/28/03

Now if you remember, I also received an oil pump along with the last order so it was time to put this one on

and be done with the old one. I took it all apart, removed all the sharp

edges inside, ran a sandpaper drum through the oil feed hole to clean it

up (more Dremel action), cleaned it (like I did the last one because

believe it or not, they're dirty inside) then put it back together.

After bolting it on I turned the engine over and checked the alignment

of the pump shaft just to make sure. It looked like the first time I

tried it with my old pump so to verify this, I put the distributor in to

double check. My luck didn't change because it didn't turn AGAIN!! Now

what could be the problem this time? After thinking about it for a

minute, I decided to check some clearances so I broke out the red

felt-marker and painted the surface around the area that goes through

the rear main cap. After a few spins of the pump shaft with the

distributor installed, I removed everything and checked for any rubbing.

Sure enough, the oil pump drive shaft was rubbing against the rear main

cap. Now how could this be because I checked my drive shaft with my buddies

pump and it worked fine. The only thing I could come up with was that my

buddies oil pump was old and both of mine were new so that meant that

the old one was made differently. What I had to do was machine a small

amount off the shaft to clear the rear main cap but making sure to put a

radius in the corner when I did. The radius is for strength like the

original.

|

|

|

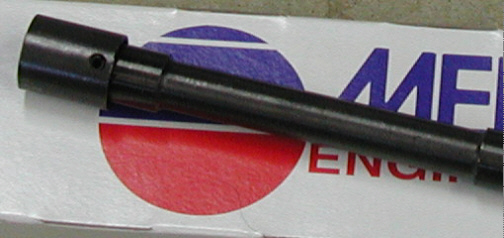

Here you can see the area I had to

machine to make this work. I only removed .100" but the area that

was hitting was only .040". This should provide enough clearance to

work now.

|

|

|

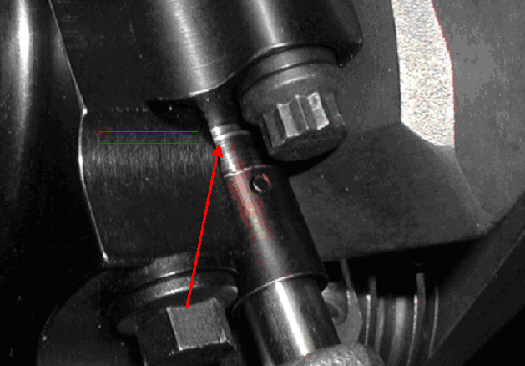

This is a shot of the pump shaft

installed in the engine. Notice the area that I had to machine (red

arrow along with the red still left by the felt marker on the drive

shaft). The distance between the green lines is about .050" to

.060". After trying the distributor again, everything worked fine.

What a headache for such a small amount of material removal.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

26 27

28 29 |

|

30

31 32

33 34

35 36

37 38 39

40 41

42 43

44 45

46 47

48 49

50 51

52 53

54

55 |

|

56 57

58 59

60 61

62 63 |

|