33 Coupe Engine 30

6/25/03

Rings and things...it's time to put

the piston rings on the pistons. This part of the engine building

process is one of the easier parts to do. All you need is a ring

compressor and a something to tap the pistons in with a soft end on it.

The soft end is so you don't ding up the surface of the piston when

installing it. Let's go through the rings that will be installed in

order. First to go on will be the support rails that came with the

pistons. These support the oil rings because of the piston pin being so

high up on the piston that the ring groove goes through the piston pin

hole. Next we have the oil rings that consist of three rings, the two

rails and one expander ring that make up the set (the two rails go on

either side of the expander). Then there is the second compression ring

and last is the top compression ring in that order.

|

|

|

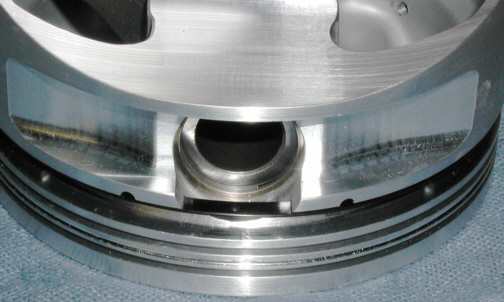

If you look close you can see the

dimple in the support rail (right below the piston pin hole). This

dimple has to be installed in this direction (dimple facing down)

because if the rail moves, it would only spin up to the pin hole and no

farther. Once all the oil rings are installed, there's no room to let

the dimple go by this area of the piston so it always stays in this spot

(trapped if you will). Now you can see why they call it a support rail

because there's no material in that area of the piston.

|

|

|

After all the rings are installed, it's time

to put the ring compressor on. This contains all the rings as they will

pass through the ring compressor and into the cylinder bore. You would

have a VERY hard time trying to do this with out a ring compressor

because the rings are all heat treated and want to stay in there

expanded shape. This keeps them compressed till they get into the engine.

After a little engine lube on the bearings and some assembly lube on the

rod bolts, we're ready.

|

|

|

|

If you notice you'll see how the valve notch is larger

on one side more than the other. There're are four like this and four

that are opposite of this. That means you have to get the right ones in

the right places. Also if you're not careful, you can put them in upside

down so you have to pay attention to what your doing.

|

|

|

|

Here I am starting the rod end of the

assembly into the cylinder bore. Once the ring compressor makes contact

with the block, it's time to tap it in.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

26 27

28 29 |

|

30

31 32

33 34

35 36

37 38 39

40 41

42 43

44 45

46 47

48 49

50 51

52 53

54

55 |

|

56 57

58 59

60 61

62 63 |

|