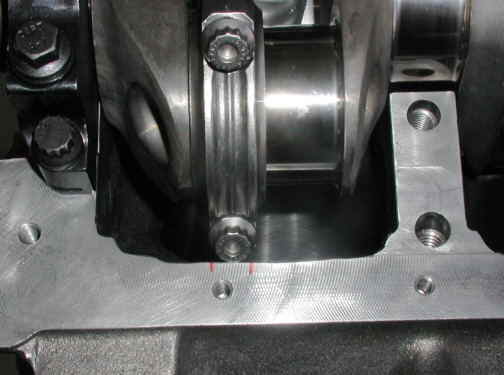

Here you can see where I marked the

block next to the rod bolt so I would know where to grind. There's a lot

of material that has to come out to make clearance for that long stroke.

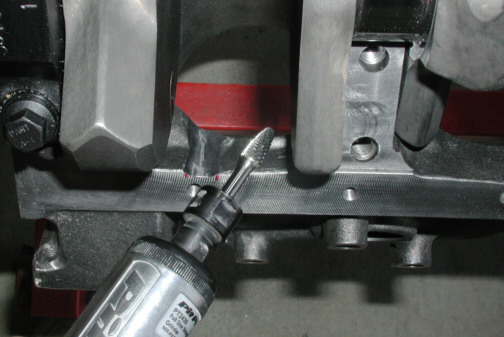

Now all we do is rotate the crank a little to make room for the grinder,

put a rag on the rod and crank and then grind and check.

|

|

|

On the last page we talked about how

thick the oil pan rails were and here is why that's a good thing. To

have the larger stroke crankshaft work, a minimum of .060" between

the rod bolt and block is the rule so that's what I made them.

|

|

|

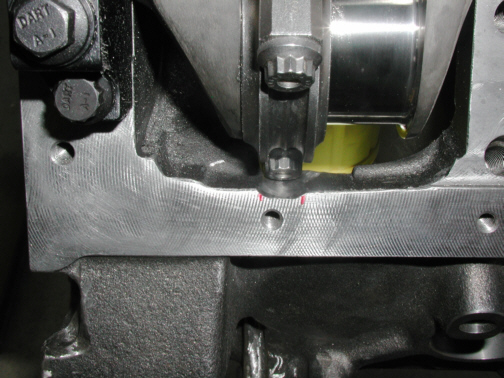

This isn't the best shot but you can

see that the bolt clears the block now. That new slot is about

.100" deep (close to an 1/8"). This had to be done on every

rod and also keeping track of them 1 through 8 in there respective

bores. As I bolted them up, I marked them with a Dremel on the rod and

rod cap. By using a small mounted wheel, it made the marking job easy

and permanent.

|

|

|

This is what the ground looked like

after I got done with all the grinding. What a mess. Now that were finished grinding, let's take a look

at more of the parts that go into it!

|

|

|

|

1

2 3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

26 27

28 29 |

|

30

31 32

33 34

35 36

37 38 39

40 41

42 43

44 45

46 47

48 49

50 51

52 53

54 55

|

|

56 57

58 59

60 61

62 63 |