|

Making Another Router Fixture

I was placing a bottle in one of the shelf cutouts and

noticed that they can slide pretty easily. That's when it hit me, what would

happen if one of the bottles worked its way to the edge and fell off?

Now I know this is unlikely, but it could happen. So I thought, why not

make a recess for the neck of the bottles to sit in?

With that being said, I made another clamp plate that was exactly like the

first one but this one will just have a thru hole and no slot. Oh, but

it will have to add a sight window.

|

|

|

|

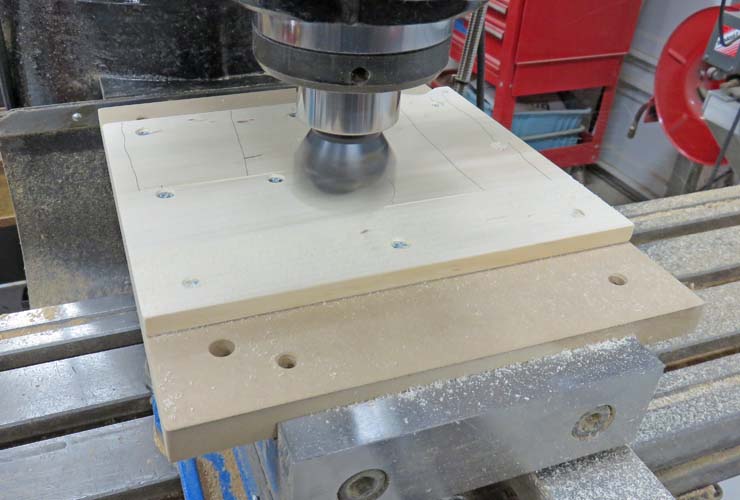

I wanted to make sure the top of the fixture was flat

because if it wasn't, the router base would follow this uneven contour so

I machined it on my milling machine. You might ask, "why didn't you just use

your planer"? A planer puts lots of pressure on the work piece as

it's going through to keep it in place while cutting the surface. So if your work piece

has a bow in it before it goes through the planer, it will still have

one when it comes out.

I put pencil lines across the top surface to make sure I

had 100% cleanup. Here you can see my cutter is spinning and is about

half way through this cutting operation.

|

|

|

|

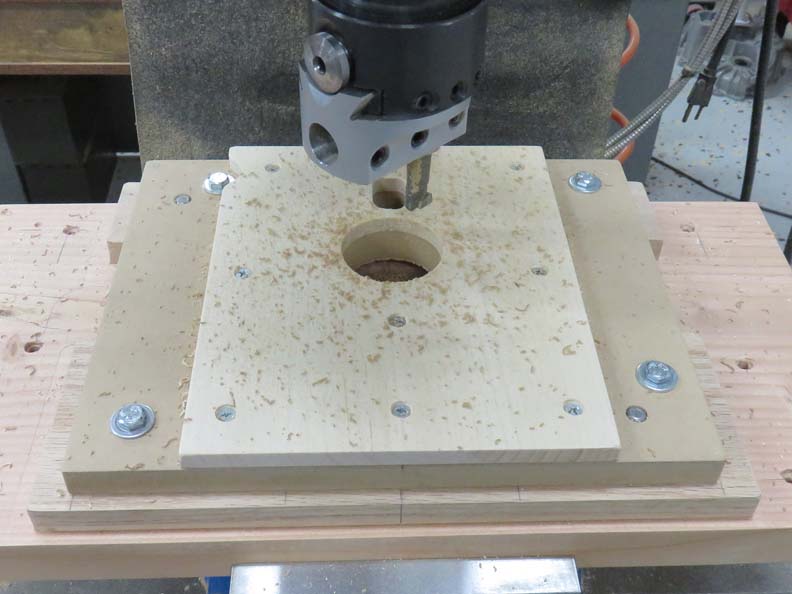

Next I bored a hole through my clamp plate. However,

after figuring out what size hole I thought would work, I didn't want to

over-shoot this dimension because this was a 'one shot deal'. So I bored my hole

slightly undersize, placed it on my router

fixture, and then checked my recess size. I gradually made this hole

larger until I had what I wanted, which took three trips to the milling

machine. If you're wondering if I ended up with the hole size I thought

would work? No, I stayed slightly under that size by .100".

|

|

|

|

The router bit that I'll be using is a bowl cutting bit

that I had from a

previous project. I

looked for a router bit that had a 1/8" radius but they were very

expensive so I used mine that has a 1/4" radius. It's not ideal but it

will do.

|

|

|

Looking down at my progress inside my fixture.

|

|

|

|

Working With Wood Continued....Again!

Here is what I came up with to keep the bottles in place.

|

|

|

This notch is .110" deep (just shy of 1/8") and works great.

|

|

|

I think this will keep all the bottles in place and it gives me piece of

mind now.

|

|

|

|

Now that the bottle shelves are finished, it's time to

install them. I made a spacer block (that is the dimension between the

bottom shelf and my new one) to help me with the installation. Once I

had the new shelf clamped in place, I put some pencil marks on the back

piece in a few places to aid me in laying out the location.

|

|

|

|

This gave me a place to layout for all my screws to hold

them in with. I used a mechanical center punch at each screw location

and then drilled each one with an extra-long 1/6" drill. The reason for

the long drill is because a normal one (or jobber length drill) was

short enough that the drill chuck would hit the sides. This long one

gave me ample room to avoid the chuck coming in contact with the sides.

Drilling Tip: Wood can be tricky to drill because of its

fibrous nature, so I like using a small drill first. The reason is

because this small drill is easier to pickup your center punch mark (and keep it

on center) than a larger drill. And once you have this first (smaller)

drill in the spot that you want, you then come back with a larger one

and it should follow the smaller one pretty good, keeping it on

location. Yes, this takes longer but it's more accurate.

Once I had this small hole on location, I turned the spice rack over and

then used a 3/16" drill, which is clearance for my screws. And last

I chamfered the back for the flathead screws.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 |