|

Working With Wood Continued

I wanted to make a small change to the height of

the cubby hole pieces along with the shelves for the smaller bottles, and after talking it over with my daughter, she gave me

the green light. I cut 1/4" off the top surface, producing a reveal. This was a

very simple change but one that looks even better than before, (at least

to me it does).

|

|

|

The next item I wanted to cut was this

shelf supports. I made it longer than I needed at the beginning and I

expected to trim to fit later. Well...now it's time.

|

|

|

After cutting it to length, I added a 3/16" radius with my router.

And again, this

small change was given a thumbs up by my daughter as she has a tendency

to bump sharp edges.

|

|

|

Speaking of sharp edges, I'm putting a 1/8" radius on the front edges of

all the shelves. This doesn't take long but the hand sanding does take a

minute to blend all the corners.

|

|

|

|

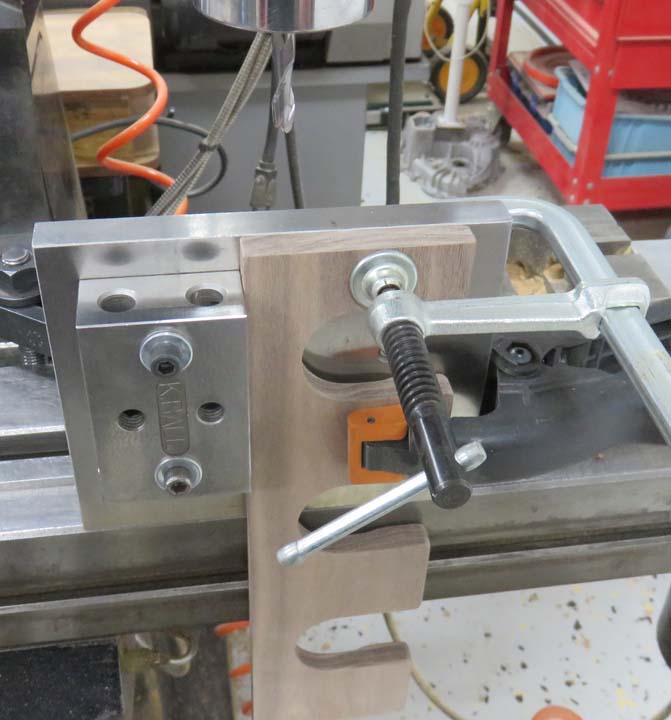

I waited to work on the dowel holes for the longer

shelves because it requires a different setup again. Here you can see I've

moved the column to the right and the ram is extended out as well (like

I did before). This is

so I can hang my work piece over the edge of the table to drill my

holes.

|

|

|

|

I made my depth the same as the other pieces, just over

1/4". But with this setup I made sure to place the edge of my work

pieces flush with the top surface of my angle plate. This way all my

depths would be the same without picking up each one with my paper

slipped between the cutter and work piece. The 1 X 2 X 3 block is acting

as my work stop.

|

|

|

I made some spacers that will be placed between some of the shelves.

This gives me the exact distance between each one.

|

|

|

|

Here you can see my spacers being used on the shelves

for the smaller bottles. This worked out great and once I had everything

in place, I marked my edges with my pencil for my dowel holes like I did

before. Now it's time to work on the shelves for the smaller bottles.

|

|

|

|

Here is the smaller bottle, and as you can see the shape

is much different than the other one. That means the shelf will need to

be made differently and will require a new router fixture to make this

happen. The size of this bottle is 2.300" tall (which includes the cork)

X 2 1/16" in diameter (in the middle). I'm going to hold these bottles

in the neck area, like I did the others, but the shape of the shelf slot

will have to be made accordingly.

|

|

|

Another Router Fixture

I'm getting ready to put in the slots for the smaller

bottles and in order to do that, I'll needed another router fixture. I ran

out of the MDF that I made the other two out of so I'm using the

top of an old oak desk that I've had

laying around for a few years. It's the perfect thickness for this,

(just over one inch) so I won't have to add a piece to the top like I

did before.

Now I'll still be able to use the bottom portion of my

router fixture, I just need a new top piece. And I'm going to make two

of these while I'm at it because it's easier to make two of them now in place of

making another single one later.

|

|

|

|

These two pieces had a bow in them so again, I'm cutting

them both flat using my milling machine. And as you can see, I've

already put in my 3/8" dowel holes and the four 1/4" hold-down holes,

complete with counterbores for the bolts and washers. In case you're

wondering why I counterbored these holes, it was necessary because the new pieces are

1/4" thicker than my other ones.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 |