33 Coupe Engine Install 40

01/01/04

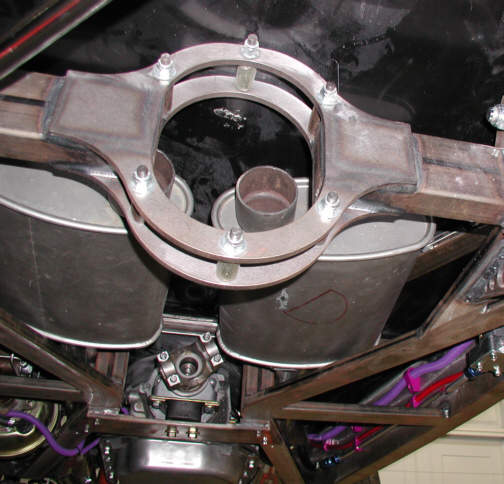

Yeah....I know you want me to do some

exhaust work for you too. I borrowed some mufflers from a buddy of mine

to use for starting purposes' only. The reason for this is if anything

were to go wrong with the engine, I might be able to hear it and shut if

off in time to save it. It's the little things like this that sometimes

make the difference.

|

|

|

|

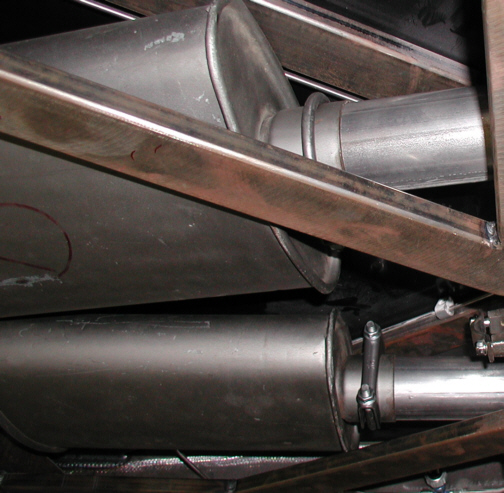

I bought some muffler clamps to hold

them on with. I might be able to use these clamps later when I finish

the exhaust system.

|

|

|

Oh....and I can't forget to add the

fluids. I used Castrol for the transmission and engine fluids. The

engine oil won't be in there but a short time and then it gets changed.

Remember, the engine takes seven quarts plus what's in the filter.

Speaking of the oil filter, I always put oil in the filter BEFORE I

install it. The reason is this, the oil goes through the filter before

it goes anywhere else so this way the engine doesn't starve for oil when

you first start it. If your wondering what the two on top are for,

that's the rear-end oil. Now this came with my chassis when I bought it

if you remember way back in the chassis section.

|

|

|

I also didn't want to forget to

install these converter bolts. These

ARP

7/16-20 bolts needed to be installed after the engine was in and after the

battery was hooked up so I could turn over the engine to get at each

one. After unplugging the electric fuel pump, it was time to smoke test

the electrical system so I placed both battery cables on and clamped

them down. I didn't see any smoke or here any pops so this was a good

sign. After turning the key to the "on" position, I did here a

click but that was it. Turning it to the "start" position, it

WORKED...woohoo! Hot damn baby...things were looking good. So I bumped

the engine over a little at a time to access each bolt so I could

install them. Now this is where my luck ran out because the bolts didn't

line up. Nothing new here so out came the Dremel again to help out.

After grinding on the flywheel bolt holes a small amount, all the bolts

are now tight. I don't know if the flywheel or the torque converter was

the problem here. I do know, like I said before, that the quality

control these days sucks big time. On the other hand, the electrical

system seems to fine and working. Kind of a sigh of relief to know the

starter works. It won't be long now till I can either hear the engine

run...or take it back out and see what I did wrong so stay tuned either

way!!

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26 |

|

27

28 29

30 31

32 33

34 35

36 37

38 39

40

Main 33

Coupe Page

|

|