33 Coupe Chassis 29

7/18/03

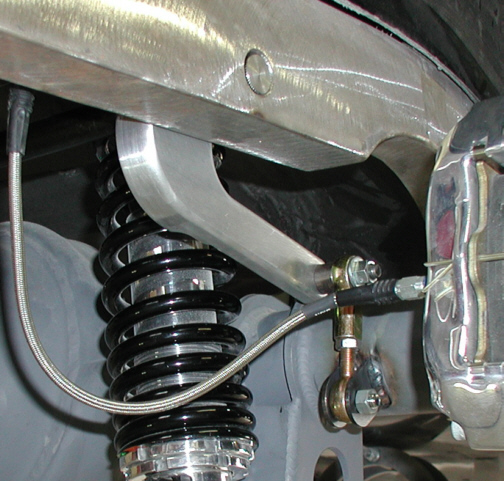

This is a shot looking from the

outside of the car. This was a lot of work but should work. Remember

awhile back when I talked about the sway-bar being weaker? Well it is

but taking into account the fact that the new arm is shorter by about

3", which means the sway-bar will be stiffer. I decided to cut the

square into the sway-bar which reduces the size of it, which also means

how stiff it is. This bar is really just a spring if you think about it

so if the spring is smaller, it's also not as stiff which is why I made

it like this. The only thing I worry about is if the Aluminum arm takes

the stress and doesn't try to spin on the sway-bar. This is also why I

used a 1" thick piece of material so it would have a larger bearing

surface and then reducing the size down to 1/2" where it didn't

need as much strength. All this just for a larger tire.

|

|

|

| 1/17/04

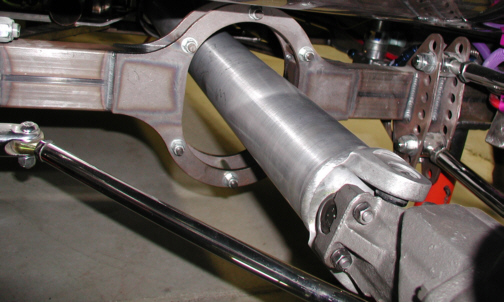

It was time to buy a driveshaft so that meant I

had to do some careful measuring. I bought mine through

Inland

Empire Driveline and they have a work sheet that you fill out that has numerous

dimensions on it. This makes it easy to figure out just what length

driveshaft you need. After filling out the work sheet, it was time to

order one. Now when buying a driveshaft, you have three choices of

material to choose from: Steel, Aluminum or Carbon Fiber. Steel is the

cheapest but weighs the most. Aluminum, weighs about 50% less than steel

but will cost you at least another "C note" more. Then there's

Carbon Fiber which is way out of my price range but weighs even less than the

aluminum one. I went with the aluminum piece which included the 3 1/2"

diameter shaft, both U-joints and transmission

yoke.

|

|

|

Now because I have a 4L80E

transmission, the yoke is a little different but not by much. The yoke

for my trans is the same as a Turbo 400, which is a good thing because

there're strong but it had to be bored out. This had to be done to clear

a seal inside the transmission. Speaking of yokes, you have choices of

different materials here too. You can get one made out of aluminum,

which has less rotating weight and weighs less, or one made of of forged

steel. The yokes come in three different sizes, 1310, 1330 or 1350

Spicer series. I choose the steel 1350 series which is the strongest out

of the three. This means that the U-joint is the strongest too. Notice

the small square welded on the tube. There is one on each end for

balancing the whole assembly.

|

|

|

This is how it looks when I bolted it

up. Now the center section isn't really a driveshaft hoop because it's

in the middle of the tube. A driveshaft hoop needs to be within six

inches of the front U-joint so this wouldn't pass NHRA tech inspection if I

were at the races. I guess it's time to make my own.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18 19

20 21

22 23

24 25

26 27

28 |

|

29 30

31 32

33 34

35 36

37 38

39 40 |

|