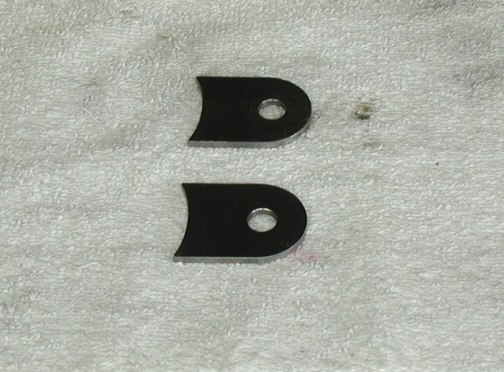

I also made these brackets that will

be welded to the rear-end housing. These are made out of mild steel 1/8"

thick and have 3/8" diameter holes. There will be two per side.

|

|

|

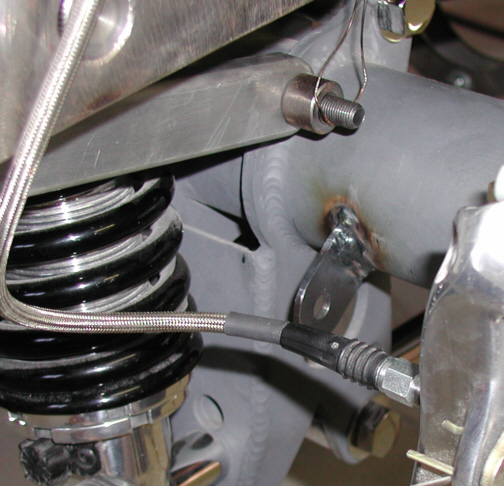

Here you can see the adjustable link

that will attach to the brackets. The other end goes to the new arms and

bolts on with a with a 3/8" flathead screw. The main thing when

welding on these brackets is to make sure the link assembly is straight

up and down when finished. If the arm is at an angle, no problem but the link has to

be vertical.

|

|

|

This is the first of the two brackets

that gets welded on. I had to weld the inside of this one because you

can see how much is in the way on the other side. The second bracket

gets welded on the outside.

|

|

|

Here is the link assembly that will be

held in place by the two brackets. Notice the paper on the bolt. This is

card stock and is about .012" thick but is being used as a spacer.

Now that the first bracket is in place, it's time to locate the other

bracket with the link and paper. This way things fit easily.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18 19

20 21

22 23

24 25

26 27 28 |

|

29 30

31 32

33 34

35 36

37 38

39 40 |