After cutting out the piece, I was

left with a hole to cover-up. The new piece was going to be 1/4"

thick and this hole was 5/8" tall. I needed something to cover this

up first and then add the new bracket or I would still have a hole when

I was through. I was going to add a piece that was 2" X 3/4" X

1/8" first and that would give me something to weld the 1/4"

piece too.

|

|

|

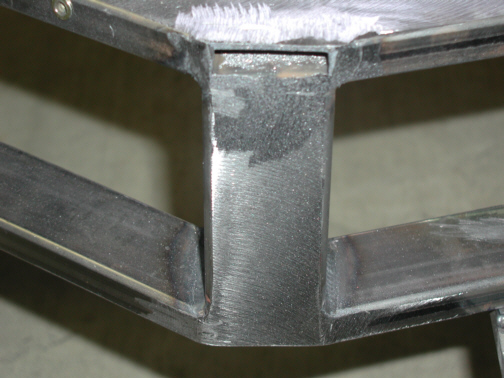

This is what it looks like with the

hole covered up. This new piece sits flush with the top surface and the

1/4" piece will do the same. The new piece is made from mild steel

like the chassis. I also added a small chamfer to the top surface before

welding to get some penetration which adds strength.

|

|

|

The new piece is 8.950" X

1.900" X 1/4" and is made from mild steel. This piece will tie

in the chassis on the top like the one I cut out. I thought about

leaving it out all together but the chassis wouldn't be as strong. Gotta

have all the strength we can ya know...

|

|

|

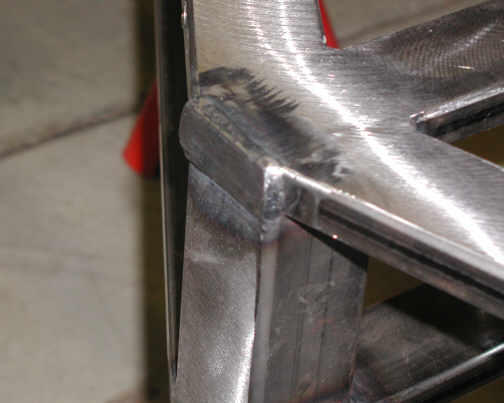

Here you can see the weld preparation.

By adding a chamfer, the weld can end up being flush when done and get

better penetration for added strength.

|

|

|

|

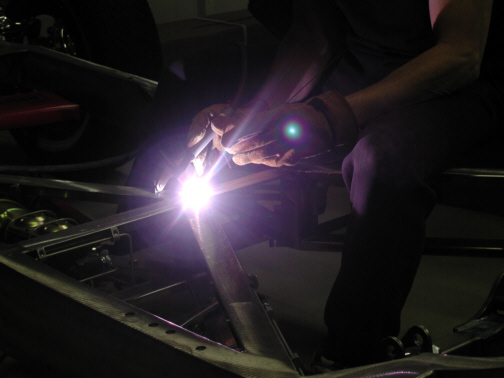

First I tacked it in and then I put

some weld on both sides to make sure it wouldn't come loose. The shot

below is of the top (the easy side) which I welded first. This new

welder sure does work good!!

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18 19

20 21

22 23

24

25 26

27 28 |

|

29 30

31 32

33 34

35 36

37 38

39 40 |