|

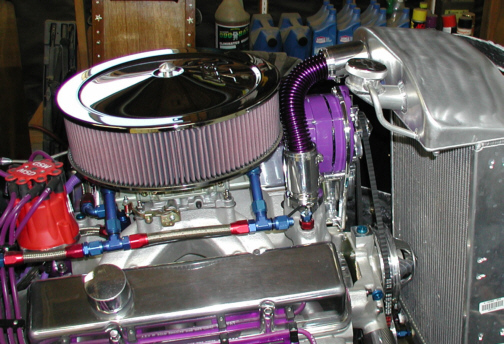

Here's

something that went a little smoother. I bought and installed a new thermostat housing which is made by

Billet

Specialties.

It has a straight neck in place of the 45 degree swivel model that I had

on previously. By using this straight style housing, the radiator hose doesn't have as many bends

in it like my old

one did and works well with my new angled radiator. The new one has

an O-ring on the bottom like the other one had which is a much better way of

sealing than a gasket. I also had to cut a new length of radiator hose

because the new one had to be 2" longer than the old one. This hose is so

strong that I don't think I'll need a top radiator bracket to help

support it. I guess I'll see how this treats me and add one if I need

it.

|

|

|

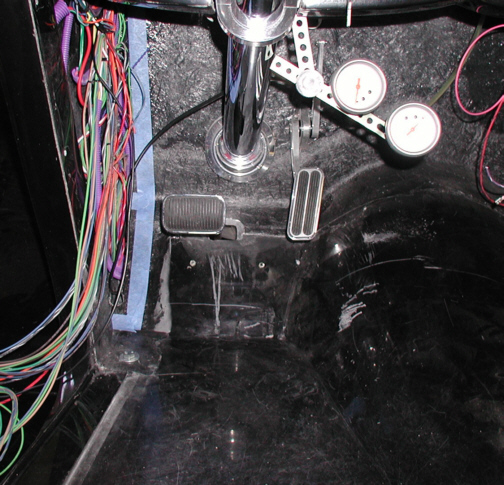

This is my brake pedal that I was

waiting to see if I needed to change the end on or not. I was undecided

of where

the brake pad that screws on the end should be located. What I mean is, I couldn't

decide how much clearance I wanted between my throttle pedal and brake

pedal. After trying my foot in several locations,

simulating various positions, I cut the end off and then welded

it back on so

the pad would be on the left side of the arm. This would give me more

foot room between the throttle pedal and brake pedal. The end was only

tack welded on from awhile back so cutting the end off was very

easy.

|

|

|

Here is what it looks like installed.

Now this car doesn't have much foot or leg room but this setup should

provide enough clearance between the two pedals for comfort and safety.

With the pedal to the left of the steering column now, it also gives my

foot more clearance too. The hole size in the firewall ended up twice as large after shortening

the arm sometime ago but it's just the right size at this point to get the pedal in

and out now that the new tab is on the opposite side. Funny how things

work out sometimes.....I mean....I planned it like that :-]

|

|

|

Here you see some 1 1/4" PVC pipe that

I picked up at the hardware store. Can you guess what I'm going to use

it for?

|

|

|

This should give you a better idea of

what is going on. I'm mocking-up a roll cage that I'm trial fitting at

this point. This 1 1/4" PVC is 1 3/4" diameter on the outside

which is close to the 1 5/8" diameter steel tubing that I'll be

using. This will be an eight point roll cage when I'm done and should

pass the NHRA tech because any car that runs faster than 10:99 has to

have a cage. Now I'm not sure how fast my car will go but I think I'll

be happy that I added it. The picture below is of the main hoop that

will go right behind the seats. The reason I'm mocking up a roll cage is

because a car like mine doesn't have much room behind the top of the

main hoop and rear of the car where the down-bars have to go through

into the trunk. I'm allowed to put the down-bars within five inches of

the top of the main hoop according to the NHRA rule book which would

give me some much needed clearance. The down-bars also have to be at a

30 degree angle or more from the vertical which is the problem. The

angle of the down-bars as the pass through the rear wall into the trunk

gets to close to the body and tries to cut into it and would show from

the outside. Now I'm not going to let that happen so this mock-up should

provide me with the best way of running the bars down into the trunk and

when I have a working solution, I'm then going to have the tubing bent

to my specifications. This way I won't be trying to engineer it when we

start bending and have something I'm not happy with in the end. Every

point at which the cage comes in contact with the floor or trunk is

suppose to get welded to the frame. You are allowed to use a 6" X

6" X 1/8" steel plate on both sides of the floor and then use

four 3/8" bolts to sandwich it together. The tube then gets

welded to the plate on the inside of the car but I have a different way

that I'm going to attach the tubes to the frame. I'll talk about that a

little later so for now, I'm going to start planning for a

cage.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28 |

|

29 30

31 32

33 34

35 36

37 38 39

40 41 |