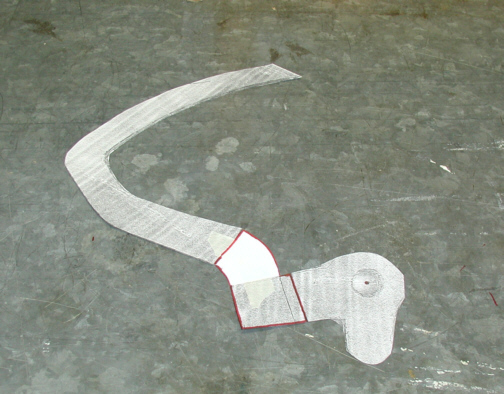

You can see the area I needed to make

after cutting the original in two places. The "red" outline is

the shape of the new piece that would have to be made. Now this would acutely

change three things when finished... (a) This would hug the firewall

much closer to give me some much needed room for headers, (b) By making

the arm straight (no bend anymore), I would have the arm come out in a

better location inside the car. This would put 1 1/4" of added

distance between the gas pedal and brake pedal. I was going to relocate

the brake pedal mounting tab even if I didn't do any of this, (c) The

arm was sticking into the engine compartment so much that only a small

amount was inside the car so this way it would lengthen the arm in that

area too. I was going to add the needed length at the time I was redoing

the tab because it wouldn't work with that short of a throw, so this change

was a "win-win-win" situation.

|

|

|

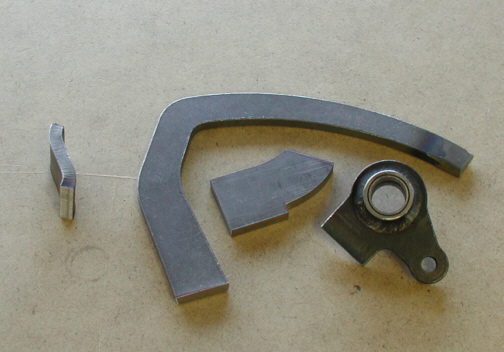

Here is the arm all cut up. The piece

on the left that has an "S" shape to it has been eliminated completely.

The new piece taking it's place is in the middle of the other three.

Let's tack weld them together and see how things fit.

|

|

|

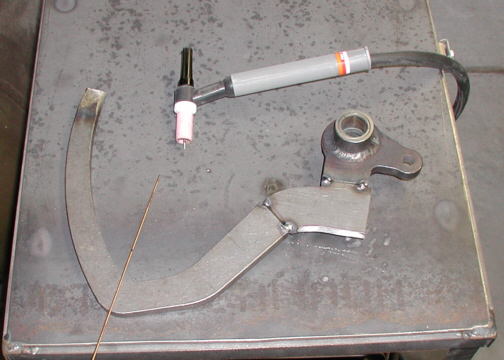

This part is critical because I need

the same distance between the center of the pivot point and the farthest

part of the arm so the pedal will come out in the same place in the

floor. This distance is 8 3/4". By laying the pieces over the paper

template, I was able to align the assembly for welding.

|

|

|

Here you can see the tack-welds only.

This is just in case things don't work right. It looks the same on both

sides. What you have to be careful of is only putting one tack on each

side. Then turn it over and put one on the other side or you run the

risk of the tack-welds pulling the one of the pieces to one side. What

you see here has been turned over many times to get to this point. I

checked the 8 3/4" dimension to make sure things didn't move and

they didn't so it's time to see how it fits before final welding. It's a

lot easier to break apart tack-welds compared to a fully welded part.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12 13

14 15

16 17

18 19

20 21

22 23 24

25 26

27 28 |

|

29 30

31 32

33 34

35 36

37

38

39

40 41 |