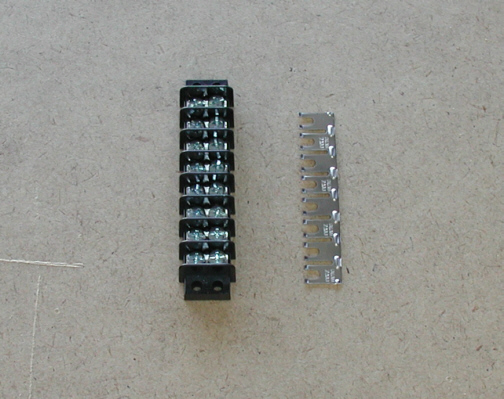

| Gett'n grounded.

With the car being fiberglass, I won't be able to

just hook a wire any old place like a steel bodied car, so that means

I'll have to do some extra work. What I came up with to make sure things

were grounded well was a central area that most of the ground wires

could connect. A terminal strip will be used and placed to the right of the MSD controller.

The piece to the right will be used in place of jumper wires.

|

|

|

|

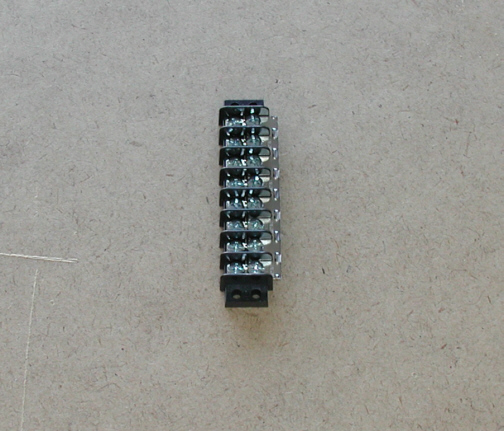

Here you can see it installed and

screwed down. This makes it much easier than cutting, stripping and then

hooking it to each lug.

|

|

|

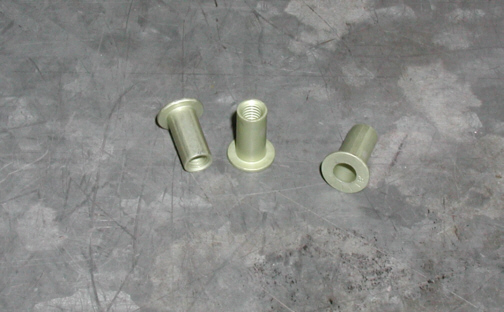

These are Riv-nuts and are made out of

aluminum. They are based on the same principal as a pop-rivet (by the

way they are installed). They have threads inside of them but not all

the way through. The reason for this is because of the way they get

installed. If you look at the one with the shoulder facing you, it

doesn't have threads at the end but you can see the others do which is

on the opposite end. When you install them, part of the small diameter

gets squeezed that's next to the shoulder. They come in a variety of

thread sizes and the one I'm using today is 10-32. I also have some in

6-32 and 8-32.

|

|

|

This is a home made Riv-nut installation

tool I made. First we have a 10-32 Socket Head Cap Screw (Allen head

screw), nut, washer, bearing, washer and then the Riv-nut. The first

thing you do is drill a hole the size of the body and in this case, that

would be .250" or 1/4". After the hole is drilled, you insert

the Riv-nut along with the installation tool. I threaded the screw in

till it just came out the back and called that far enough. Next you run

the nut down till the washer, bearing, washer touches the Riv-nut. Now

all you do is use an hex-key (Allen wrench) to hold the screw and turn

the nut with a wrench. You only have to turn the nut two or three turns

and that's it. Let's see what it looks like after it's installed.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 |

|

29 30

31 32

33 34

35 36

37

38 39

40 41 |