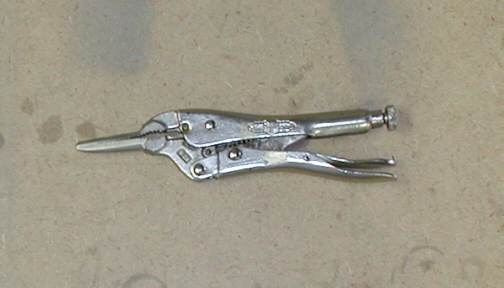

I took a pair of needle-nose

vise-grips and ground down the nose. Does it look like a dolphin to

you....or is it just me? I also removed the serrations that are inside of the jaws because they are very sharp. I was now ready to start some

surgery.

|

|

|

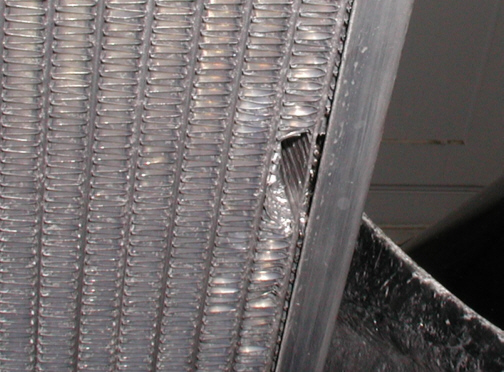

What we have here is the problem area

to work on. I made room for my newly ground tool with a six inch scale

and was now ready to get to work. The reason I used my six inch scale is

because it's thin (unlike a screwdriver) and flex's easily which means I

would have to take my time. One wrong move with a screwdriver and I

might have two holes to fix. I then started squeezing the tube from the

top to the bottom around the hole and then moved inward about a

1/2" and repeated the process over and over till I had reached the

rear of the 1 1/2" tube. My plan was to see if I could reduce the

amount of water that was coming out at all. Now this tube is only

.075" thick to start with and water has to run down the center of it which means

the tube has a VERY thin wall. This is why I removed the serrations from

the jaws before I started so I wouldn't poke or produce another hole. After

I was finished crimping the tube, I refilled the radiator and watched to

see if I had done any good or if I made a sprinkler system. It was

peeing out the first time and now it was just seeping. This is what I

was hoping for. At this point, I didn't have much to lose and I had one

more ace up my sleeve....I think!!

|

|

|

I went down to the parts store and

bought some stop leak made by AlumAseal. I had nothing to lose and

everything to gain. All I had to do was pour it in the radiator, top it

off with water, put the cap on and drive the car till the leak stops.

Now I'm not able to drive the car yet so I started it up and ran it for

15 to 20 minutes. I would have run it longer but I don't have a fan on

it yet so I turned it off when the temp gage reached 190 degrees. Well

for a buck eighty-five, this did the trick and I couldn't be

happier :-] AlumAseal says that the fix would be permanent

so I guess I'll have to see what happens. For now, I'm very

happy....again!!!

|

|

|

Now that the radiator seems to be

fixed, I'm ready to finish the over-flow container. What I did was turn the

container upside-down to use it. I'm using a brass 1/4" diameter

tube that runs from the top to the bottom of the container that is cut

to within a 1/4" of the bottom of the container. This way when the hot

coolant starts to over-flow into the tank, it will have a way of

returning to the radiator. I drilled and reamed for a press-fit in the

fitting below. The fitting has 1/8" pipe on one end and 6an on the

other. I opened up the end with the pipe threads as it had a step inside

it so this way, the step is almost gone now. The brass tube measured

right at .250" so I reamed the hole .2495" for a light press

fit. The other end will be getting some braided steel hose running from

the radiator to this fitting.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21

22

23 24

25 26

27 28 |

|

29 30 31

32 33

34 35 |