Here you can see one of the upper

mounting blocks bolted in place with two 8-32 stainless button head

screws. I used a 3" diameter air powered cut-off wheel to rough it

out and then used my Dremel to get it close. A file was used to final

fit all the blocks. To get the location for the screw holes, I inverted the

blocks and scribed a circle down through the threaded holes. After I had a

small circle on the hood, I center punched the location and drilled the

holes. After installing all of the upper mounting blocks, I placed the

hood back on to see if it fit, and...booya....it fit.

|

|

|

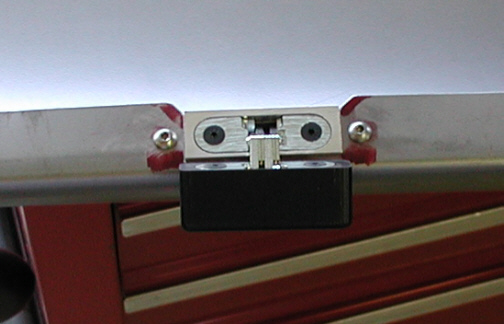

Here is a close-up of the hinge

installed on the hood. I made some small angle cuts to have it blend

better to the sides. The black part of the hinge that you see are made out of plastic

and these go inside the bottom mounting blocks. This way there isn't

metal-to-metal so things won't rattle.

|

|

|

In this shot you can see all four

upper hinges installed. The ones on the right are open and the left ones

are closed. Now it's time to install the hood props so the hood needs to go

back on.

|

|

|

Here is what the hood props look like. The prop-rod and nuts are made out

of stainless, the prop-rod holder is plastic and the upper mounting

block is aluminum. At this stage of the hood hinge installation, this

was the easy part. All that is needed is drill two 5/16" diameter

holes 1/2" away from both bottom mounting blocks.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21

22

23 24

25 26

27 28 |

|

29 30 31

32 33

34 35 |