33 Coupe Last Details 24

6/04/04

This is looking pretty good so far but

does it work? It sure does and it didn't cost me a dime....only some

time! The one thing that I might have to do is increase the ratio of the

pedal if it doesn't work as planned but that's easy too. I now have a

4.3:1 ratio and can increase it to 6.5:1 by drilling a new hole

3/4" from the existing one.

|

|

|

Here you can see what I'm talking

about a little better. By adding a new hole upward by 3/4", this

would increase my ratio to more of what it should be but I'll see how it

stops when I take it for a "real" test drive. I'll also need

to make a new spacer that goes between the brake pedal and push rod

bearing. I had to add four 3/8 washers and a longer bolt so the push-rod

would be on center because the existing spacer wasn't long enough. When

I tear down the car for paint, this will be on the list of things to do.

I now can remove the vacuum line that runs from the engine to the

underside of the car as it's no longer needed. Oh....and that driveway

test drive that I wanted to take earlier, that had to wait till the next

day, but was worth the wait. Let's just say, I know the posi-traction

unit works!!!

|

|

|

| 6/13/04

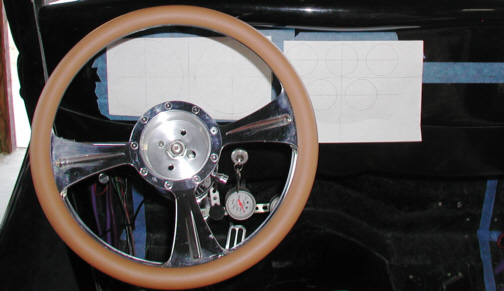

What I'm getting ready to do is install my

Autometer

gages

and if you've been following along, you might have seen this layout from

time-to-time in some other pictures. What you see below are some paper

cut-outs of some Autometer gages that I printed and then placed onto the

dash to give me an idea of what I wanted. By placing the cut-outs in

different locations, I finally decided on the pattern that I wanted. I

didn't want to install the gages till my seats arrived because I wanted

to be able to see all the gages while I was seated and do this procedure

only once.

|

|

|

To layout the dash and make sure the

gages were centered, I first used some tape to go from one end to the

other and then I marked off some center lines. Now I needed two

different vertical centers for my layout, one for the larger gages and

one for the smaller ones. Then I used a compass to draw some circles on

a piece of paper to get the layout that I wanted. What I wanted was the

gages to have the same distance between them all, no matter where you

measured them at. Once I was happy with the results, I matched the center

lines on the paper with the centerlines on the tape. At this point, all

I needed to do was transfer the centers to the dash. I used a 1/16"

diameter drill in my electric drill motor for this task but didn't go

through the dash. What this did was give me seven small dimples in exactly

the location that I wanted. I then removed the paper and tape and

then used some dividers to draw my circles to the size needed.

Dividers have points on both ends which meant that one would go into the

small dimple that I just drilled and the other would scratch the surface

of my dash giving me a reference to go by. Let's break out the drills

and Dremel and get to work.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21

22

23 24

25 26

27 28 |

|

29 30 31

32 33

34 35 |

|