|

Getting Fancy Continued This is the front panel and it has the same pattern at

the bottom as the back panel, which makes this one easy. I used my

Milwaukee jig saw for all the cuts but I wasn't happy with it. For some

reason it will cut straight for a short distance and then the cut will

have a slight angle. I messed with my saw but couldn't get it just right

so it's time to look for a different saw. That's to bad because I have a

bunch of Milwaukee M18 cordless tools but this one isn't all that.

|

|

|

|

The next step was to put some nice smooth rounded edges

on some of the surfaces, but not all of them. I'm using a 3/16

round-over bit which should look and feel nice. As you can see I've got

the back panel clamped to my work bench which worked really well while I

used my router. However, I only routed the edges on the top and bottom

sculpted areas and the heart.

|

|

This went fast and it came out nice. I also did the sculpted area on the

back panel, and the front surface on the lid where you would open it

from.

|

|

|

Assembly

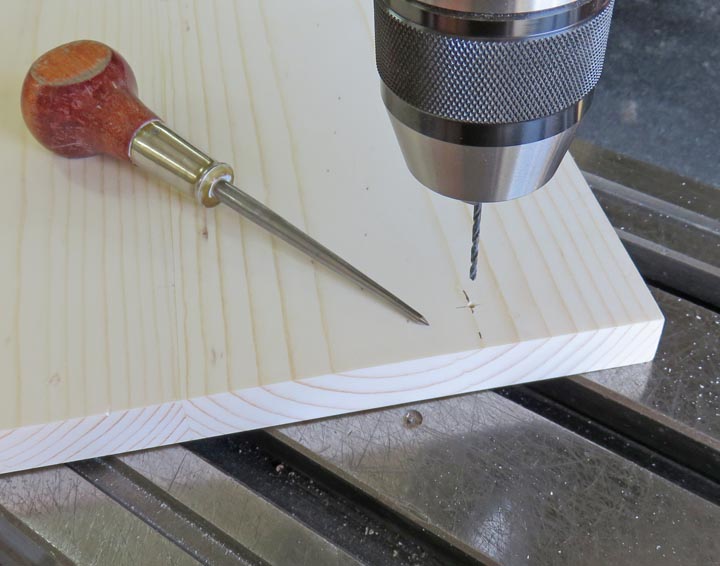

This is the side panel and I've laid out for some holes

for screws. These screws will hold the sides to the front

and back panels, seven per panel. I used my awl to make a small dimple

and then used a 3/32 drill to pick up that spot. Once I have the small

hole in the correct location, I came back with a larger drill and that

one

will follow the existing hole.

|

|

|

|

Once I had the clearance holes drilled in the side panels, I

placed each one against the front and back panels, clamped them in

place, used a transfer punch to made some dimples, pulled off the clamps

and then drilled my pilot holes. The location of these holes determine

the placement of each panel, which is critical.

|

|

|

I pre drilled the holes in the shelf cleats before hand and here I'm using my

transfer punch again to locate each piece on the side panels.

|

|

|

Here you can see what the transfer punch does. I also used my pencil to

darken the spot so you can see it better. Now all I have to do is drill

a pilot hole for my screws at the dot.

|

|

|

Once I had the box screwed together, I was able to fasten all the shelf

cleats in their proper locations.

|

|

|

This is looking at the bottom side: I'm transferring the shelf cleat

holes that will hold the shelf. Once I had all the spots

located, I removed the shelf and drilled all the pilot holes.

|

|

|

|

Now it's time for the seat supports. These need to be

flush with the top surface of the front panel. Once I had both sides in

place, It was time to locate the rear piece. As you can see I have the

rear piece clamped so I can transfer the holes.

|

|

|

|

1

2

3

4

5

6

7 |