|

Finishing The Tray Continued

I'm getting ready to transfer the hole location from the tray to the

chair. I clamped the tray in place and then by using the sharp tip of

the #10 screw, I was able to make a mark on the wood by pushing on it with a

screwdriver.

|

|

|

Here is the mark the screw left which was

easy to pickup. This will be a pilot hole for my # 10 screw but it won't

go through.

|

|

|

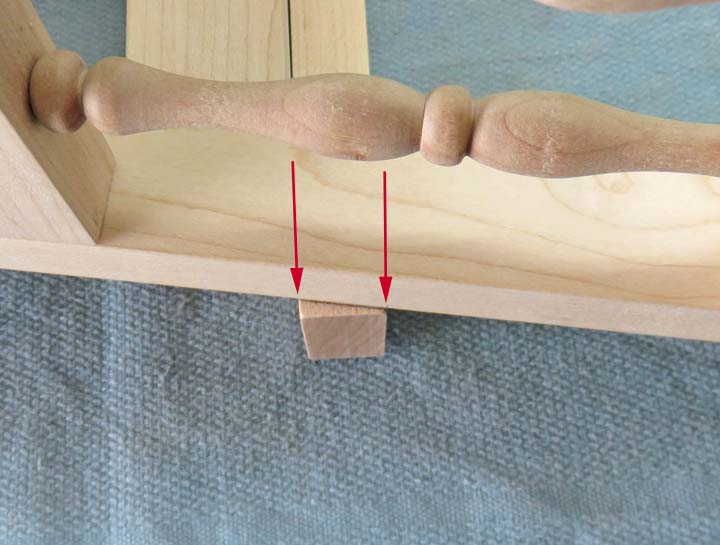

I have the chair on its side here. The area between the arrows are

pointing to the back of the tray that needs to be cut at a 10 degree

angle.

|

|

|

Once I cut this angle, it will then match the back of the chair.

|

|

|

|

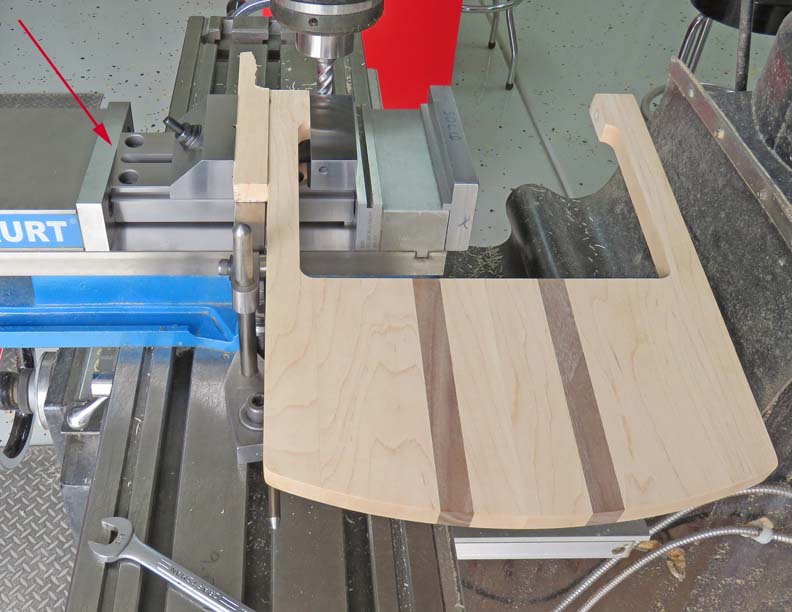

To get my 10 degree angle, I'm using my precision vise...

in my mill vise set at my desired angle. I placed my 10 degree angle

block under the precision vise and if you look close you can see the

slight difference where it's angled (arrow).

|

|

|

This worked out great and now the ends of the tray and chair back are flush with

each other.

|

|

|

|

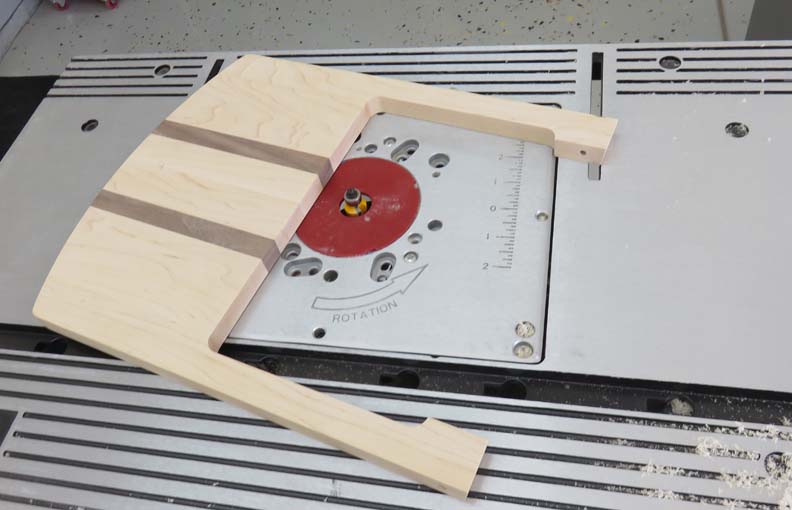

I used my router table and put a 1/8" radius on most of

the edges of the tray. In fact, did the same for most of the other pieces for

this project. Note: where one piece would cross another piece, I didn't

put a radius at those areas (like the arm rest where it comes in contact

with the arm rest support). I worked up to a pencil line and then

stopped so it would look better. You'll see what I mean later.

|

|

|

|

Cleanup Time Here is the mess I ended up with once I was finished

machining. Lots of wood chips for sure but I did leave some in the base

area of my milling machine. The reason is because of the 'lubricating oil'

that runs through the machine and finds it's way

to the bottom. This helps to absorb this oil as it's being dispensed.

|

|

|

|

Final Assembly

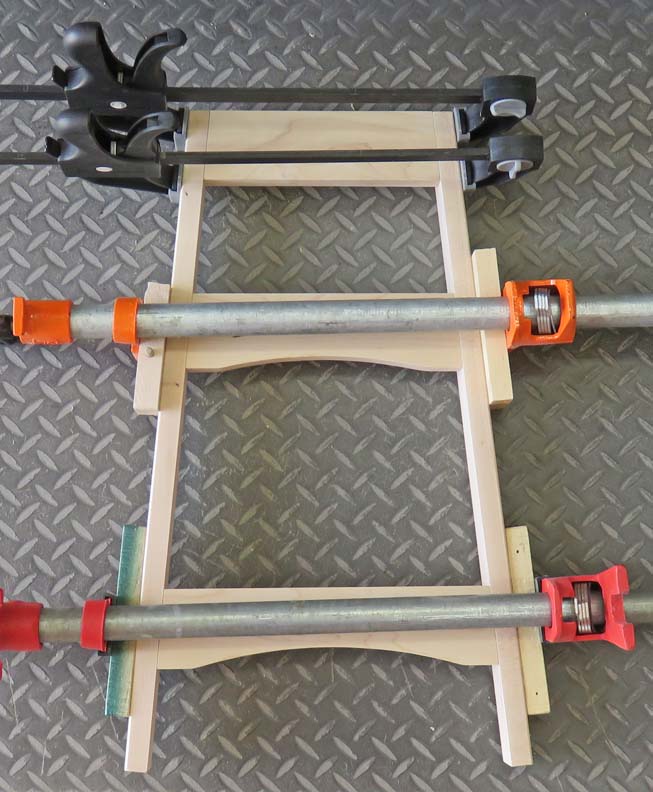

I did one last dry fit with all the dowels before

gluing. Then I put a couple of drops in each dowel hole, a small

amount between them (on the flat surfaces) and then clamped them

together. However, once I started placing my clamps here and there, some

of the joints had gaps. All I could do is shake my head from

side-to-side wondering why?

Then it hit me, I wondered if I placed too much glue in

some of the holes and that was holding my pieces apart? I'm not sure but

my plastic clamps were quickly replaced with some screw clamps that have

much more clamping force. Once I had those troubled areas closed, I

replaced some of my screw clamps with the others.

|

|

|

|

The following day I assembled the other remaining sides

and the same thing happened (gaps) so I repeated the process from above.

Once everything was dry, I used my D/A sander again and made sure all

the surfaces were flush. I also did some hand sanding here and there.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11 |