|

Here is the first one of the four to

be welded on. Now the first one was easy but lining up the others

weren't.

|

|

|

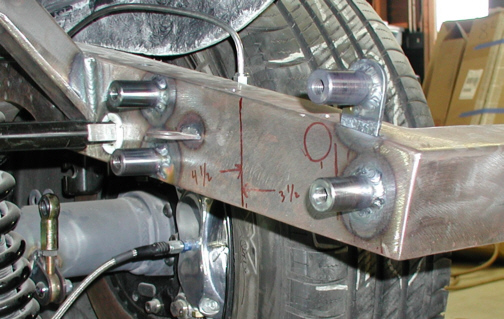

Here you can see all of them welded on

and ready for some bolts. The trick to lining up all the holes was done

one at a time. I drilled the hole in the brace on the box first and then

installed a bolt through it to hold the spacer on. This gave me the

location that I needed so things would line-up. After the two were held

together with the bolts, I clamped the assembly to the chassis and tack

welded the spacer. By doing this one spacer at a time, they all lined up

afterwards.

|

|

|

Here you can see how the box all

bolted up. Speaking of bolts, these are grade 8 fasteners that are being

used. Now this will all be covered later by a body panel. Well I had

planed to cut a hole in the trunk to access the battery from the top so

I needed to put the battery in place to mark some lines. Wouldn't you

know it, I missed the dimension by 1/8" and the battery wouldn't go

in. The hole in the trunk would have to wait till I could get the

battery in the box so out came the grinding wheel.

|

|

|

I removed the front lip from the angle

in front and smoothed out the rough edges. I have to say that this is

much easier to get that lead weight in there now. Because of the weight

of the battery hanging on just those two uprights, I needed to strengthen

things a little.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 |