Here is the aluminum fuel line I'm

going to use. It's 1/2" diameter X 25 feet long. Now this stuff is

easy to work with compared to stainless tubing.

|

|

|

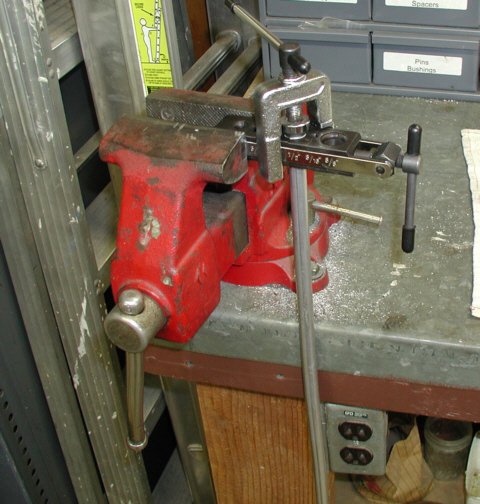

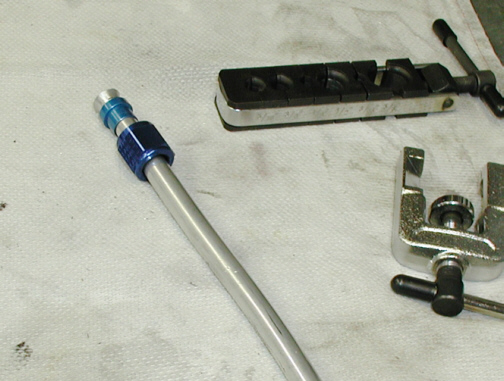

After cutting a piece 32" long, I

needed to give the end a 37 degree flare to match the AN fittings I'm

using. If this flaring tool looks familiar, that's because it's the same

one used for making my brake lines and it can handle seven different sizes of

tubing. All you have to do is make sure the end of the tubing is flat

and square with no burrs and then make the end flush with the top

surface. Clamp it in place and then put on the top clamp with the taper inside

the tube. Crank the handle a few turns and there you have it.

|

|

|

There are two parts to these fittings

that get used on tubing. The flare and the nut. If you have any kind of

bend in your tubing, then you need to put these on prior to flaring the

end. Believe me, it's easy to forget.

|

|

|

The other end needed a slight bend in

it. This bend was necessary to run from the fuel pump over to the frame

rail. The way I bent it was just by hand. I went slow and did a little

at a time. Now we're ready to test the fit.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 |