33 Coupe Fuel System 14

12/26/03

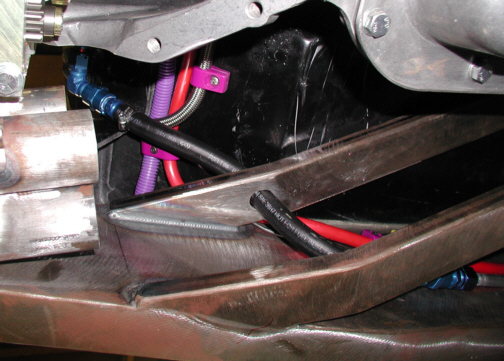

To connect the engine side of the fuel

line to the underside of the car, I'm going to use rubber hose. The NHRA

rules state, "you can use a maximum of 12 inches total (front to

rear) of non-metallic or non-steel braided hose is permitted for

connection purposes only". It also states, "fuel lines (except

steel braided lines) in the flywheel/bellhousing area must be enclosed

in a 16 inch length of steel tubing, 1/8-inch minimum wall thickness,

securely mounted as a protection against fuel-line rupture". I'll

be changing this rubber hose to the steel braided stuff when the car

gets painted because the hole that this runs through needs to be larger. This job will be much

easier when the body is off so this will wait till then.

|

|

|

|

In this shot you can see the rubber

hose passing through the section of the chassis that I drilled earlier

with the extended drills. This is the hole that will be opened up later.

This takes care of the fuel line from carburetor to fuel cell.

|

|

|

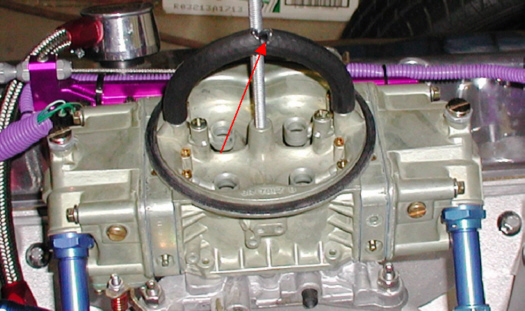

While I was in the fuel line mode, I

went ahead and placed a piece of 5/16" fuel line on both vent tubes

that are on top of the carburetor. If you've ever owned a Holley carb,

then you know what this is for but for those that haven't, let me

explain. There are two vent tubes (under the rubber hose) that go

directly into the float bowls and when you leave from a standing stop

hard enough, gas dumps out of this tube right in the mouth of the

carburetor, flooding it for a moment which causes a stumble. By putting

this piece of tubing between the two vents, along with a small open area

(the red arrow shows where I cut the tube half way through), gas flows

between the two float bowls and nowhere else. Now this also works for

hard stops as well. Just a little trick I've learned over the years.

|

|

|

Speaking of vent tubes, this piece

will be used to vent the fuel cell to the outside of the car. After

drilling a hole in the floor of the trunk large enough for the braided

line to pass through, I didn't want the line to just be sticking out and

looking bad so I made this piece to clean things up a little. The large

end is 1" diameter and then it steps down to 5/8" diameter

with a 5/8-18 thread. The small end is for the braided hose to go over

and gets held on with a hose-clamp.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 |

|