|

Machining

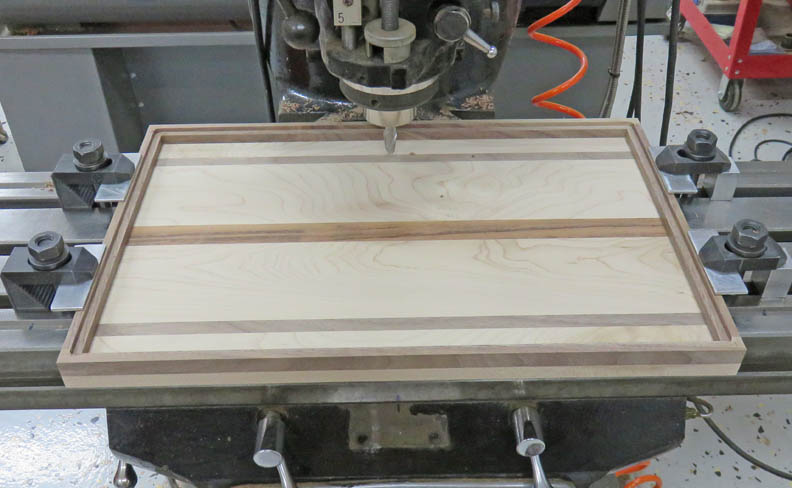

I'm cutting the step on the lid here that will mate-up with the bottom.

Here I'm using a 1/2" diameter cutter to rough the step in with.

|

|

|

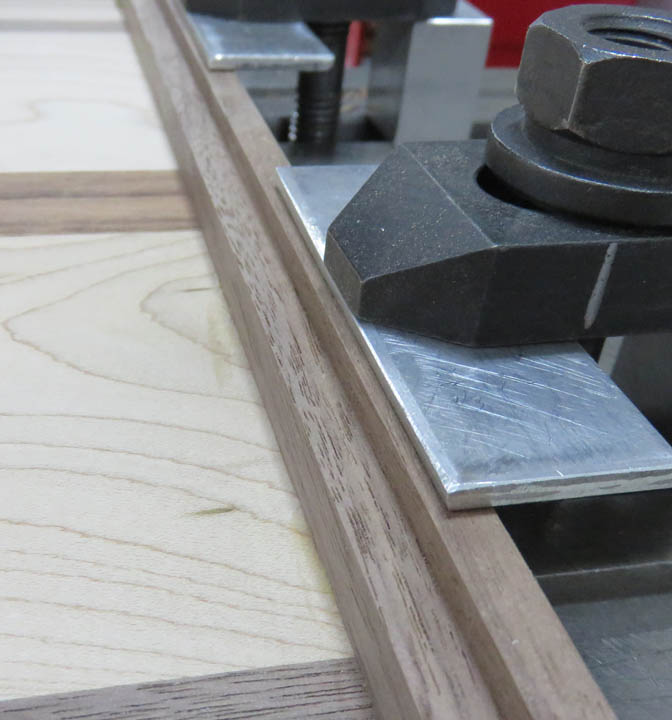

Here you can see what the step looks like.

Notice those clamps, they're right at the edge. Now it's time to finish

this step.

|

|

|

|

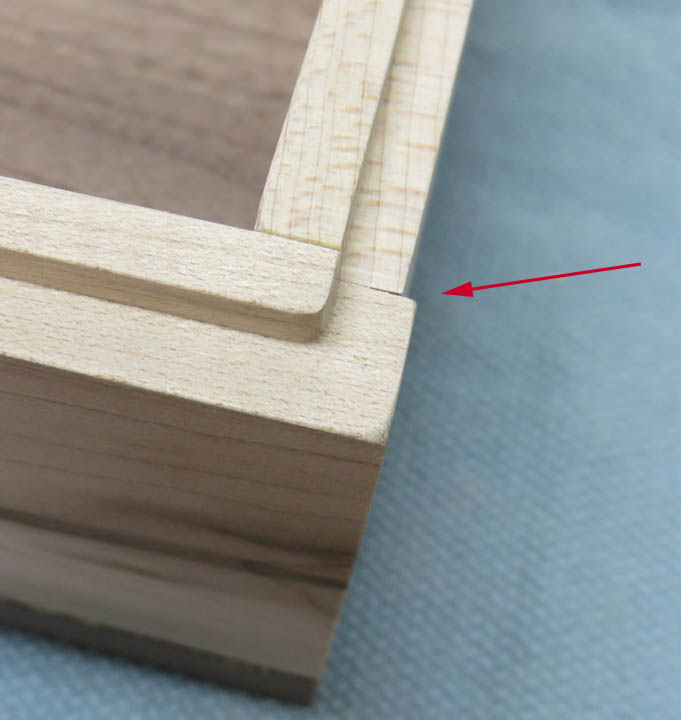

Another Problem On a side note, here is another area that needs to be

addressed from my sanding episode. See that miss-match, that just won't

do. So...because of my bad sanding, I'll need re-cut this area again

later.

|

|

|

|

Machining Again

What I'm doing here is finding the exact length from one

side to the other (of the steps) on the bottom piece. Once I have this

dimension I can cut the top to match. Now my 12" calipers are too small

to measure across the steps by them selves so I'm using some 1" X 2" X

3" blocks to help me. BTW, I'm using my granite surface plate to make

sure things sit flat.

The two outside blocks are against the step (that I want

to measure), and the the two inside blocks are against the other blocks.

This gave me just enough distance between the two inner blocks to use my

calibers and get a measurement.

|

|

|

Now that I have my dimension from above, it's time to finish the step in

the lid. And I'm using my blocks and calipers again to see how much more

needs to be removed.

|

|

|

|

I'm using a 1/8" diameter end mill to finish the corners with,

so it matches the radius I filed earlier. Once I unclamped the lid

I checked the fit and it was exactly what I wanted. I went with .010

clearance, which should be more than enough once the clear finish has

been applied.

|

|

|

|

Problems Again

A couple of days later I was messing with something and

placed the lid on the box and for some reason the lid warped. But I

don't know why this happened and now it doesn't fit correctly. See the

12" scale sitting on the top? See the 18" scale under it? And see the

12" scale is touching the outer edges of the lid? Well...that scale is .030" thick, which means the lid is bowed by that amount.

At first you might think, 'no big deal, nobody will ever

see that'. However, what you my not have noticed is gap at each end

where the lid touches the box. That gap allows the lid to rock from

side-to-side, which isn't good. It's not good in my book anyways, not

good at all. One step forward and two steps back...

|

|

|

|

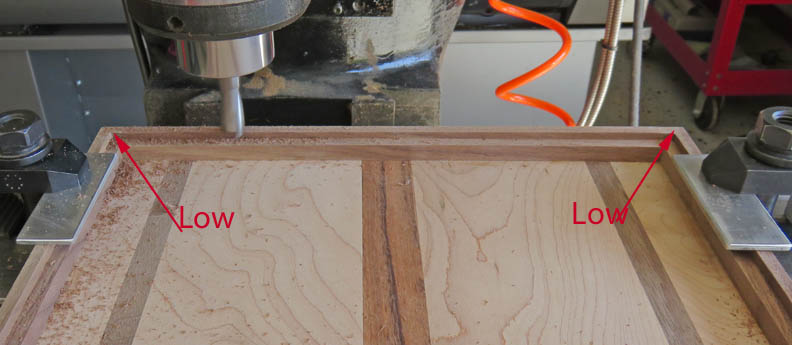

Re-Work I put the lid back on my milling machine to re-cut the

areas that were a problem, which is between the two spots marked 'Low'. I

needed to cut the top and bottom of the step so the lid would fit

correctly again. However, only the two ends needed to be reworked (not the

long sides) so it could have been worse.

|

|

|

|

More rework: As you can see there is a large step at the

top that needs to be fixed. This is the result of me sanding too much

earlier. To fix this I'll be cutting the sides with a long end mill.

That's the good news, but after the bad areas has been machined away,

I'll end up with the lid not fitting because now it will be to large.

|

|

|

|

This is the opposite end of the same side from above. I

stayed away from the end by an inch or two and then stopped, turned the

box upside-down and then re-cut this area so it blended.

|

|

|

|

1

2

3

4

5

6

7 |