|

Main Rotor Nut Clock Continued

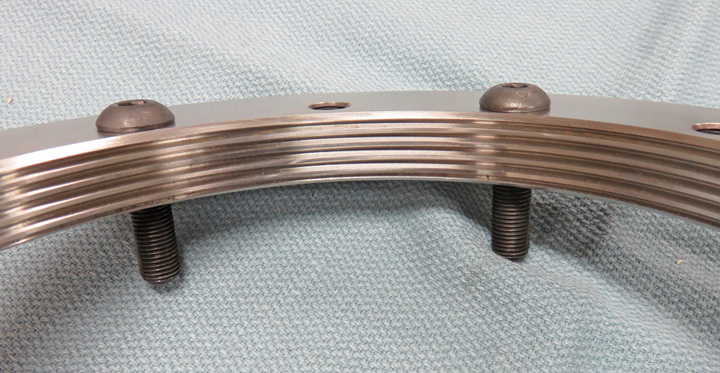

Here's a better view of the seated bolts,

which looks much better. Now it's time to make some provisions for some

hanging hardware.

|

|

|

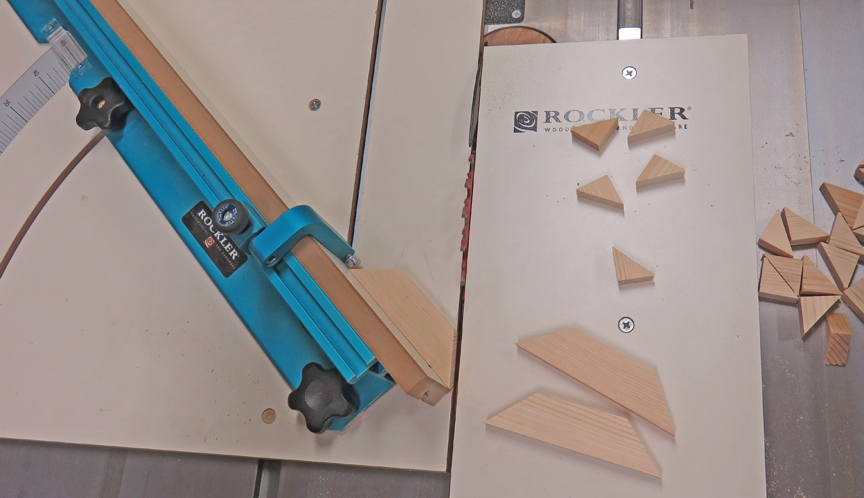

I ripped some pine to 1 1/2" wide and then I ran them all through my

planer.

|

|

|

Next I cut them all to 5" long.

|

|

|

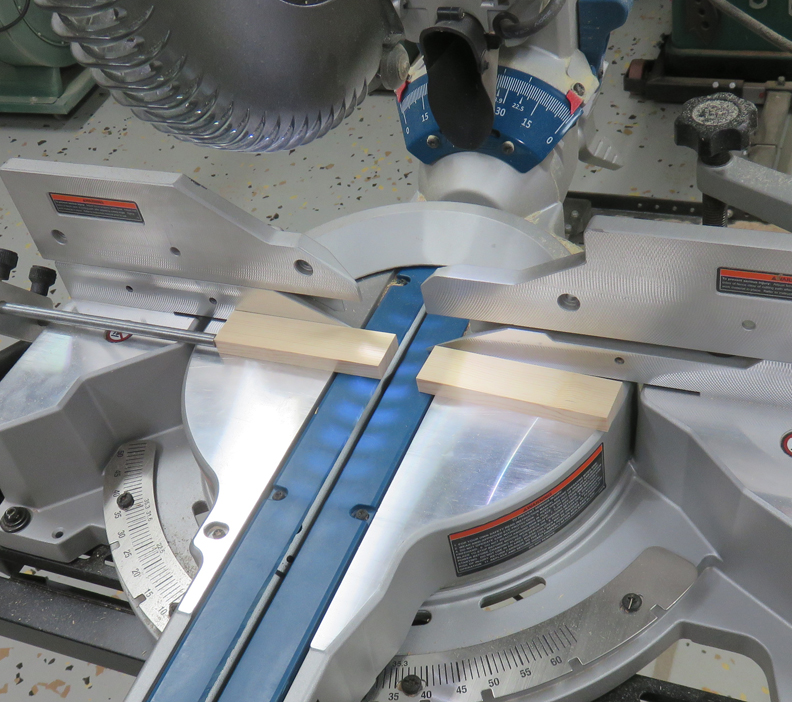

I used my cross-cut sled to put a 45 degree angle on each piece. This

works out better here than my miter saw because of the fine adjustment I

talked about earlier.

|

|

|

The next step was to attach each piece to the back. I clamped each one

in place and then used my pneumatic nailer to fasten them in place.

|

|

|

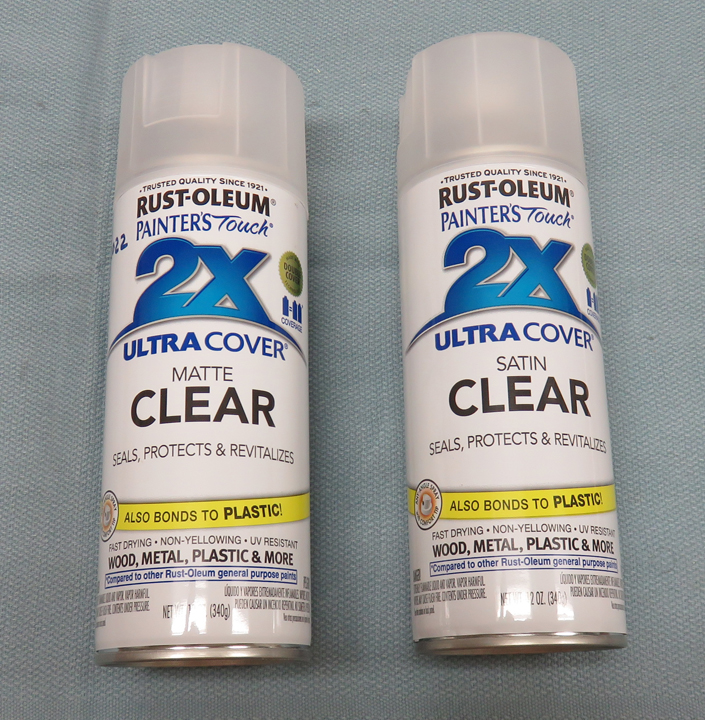

I happen to have both of these on my shelf so I used the matte finish on

the rotor nut and the satin on the wood. The reason I sprayed the metal

pieces is so they won't oxidize.

|

|

|

Just out of the paint booth (side of my yard) and almost ready for assembly.

|

|

|

|

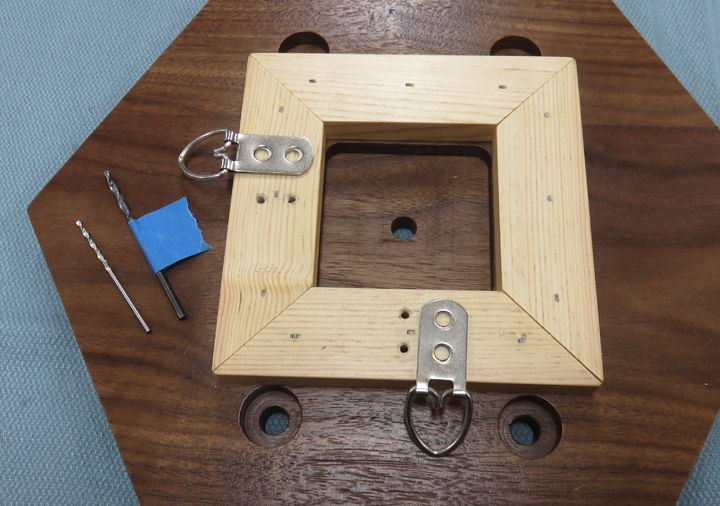

I bought a bag full of some picture hanging hardware

but I won't be using those short screws. These pieces are made out of

stainless steel and they have two holes to mount them with. I could've bought

some with only one mounting hole but these clocks are heavy, hence the

reason for the two holes.

|

|

|

I made provisions for two mounting locations because someone might like

the flats on the top & bottom, or they might like the points at the top

& bottom. This way they have choices.

|

|

|

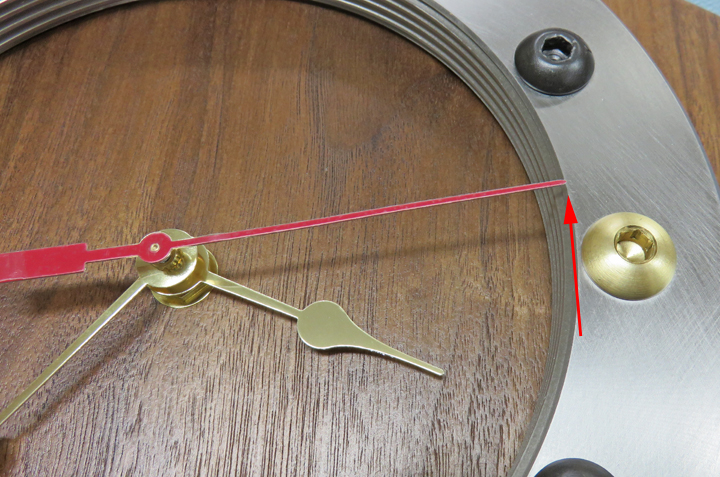

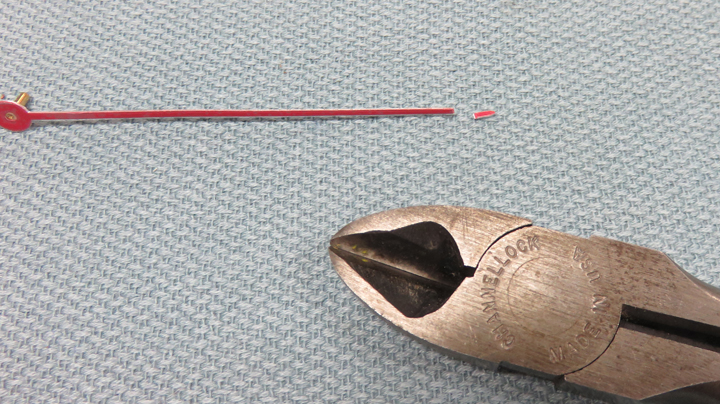

The second hand was a little too long but I knew that when I bought

them. No big deal because the hands are easy to trim.

|

|

I quick snip with some wire cutters and I'm good to go.

|

|

|

1

2

3

4

5 |