|

Main Rotor Nut Clock

I'm going to use some black walnut for this project and I'll

mount the rotor nut to this material.

|

|

|

The other pieces weren't wide enough so

I'm getting ready to add to them.

|

|

|

Then I glued them together making two separate pieces.

|

|

|

The next day I sanded both pieces and now I'm ready to start cutting it.

|

|

|

First I ran two sides through my table saw making them parallel, and then

I used my crosscut

sled to square the ends.

|

|

|

|

I drew out several different shapes to mount the rotor

nuts on, but in the end I decide to make the wooden pieces a

hexagon. I set my crosscut sled to 30 degrees and cut one end using my

adjustable work-stop to bank against.

|

|

|

|

I had to readjust my work stop for the opposite side but

once I had it set, my saw made quick work of those angles. Side Note: I

added the thumb-screw (arrow) to my adjustable work stop which makes

fine adjustments a breeze now.

|

|

|

Here is what it looks like once I gave it a light sanding. Now it's time

to look at the clock movements.

|

|

|

|

I bought these clock movements at a place called

Clock Parts.

I've used them before on another project because they have a bunch of

choices. In the end, I chose a movement with a silent second hand in

place of one that goes, tic, tic, tic. You also have your choice

of hands that come with your movement: long ones, short ones, different

colors, you name it. And you also have your choice of shaft lengths too.

I went with brass hands so they will match one other item I have in

mind for this clock.

|

|

|

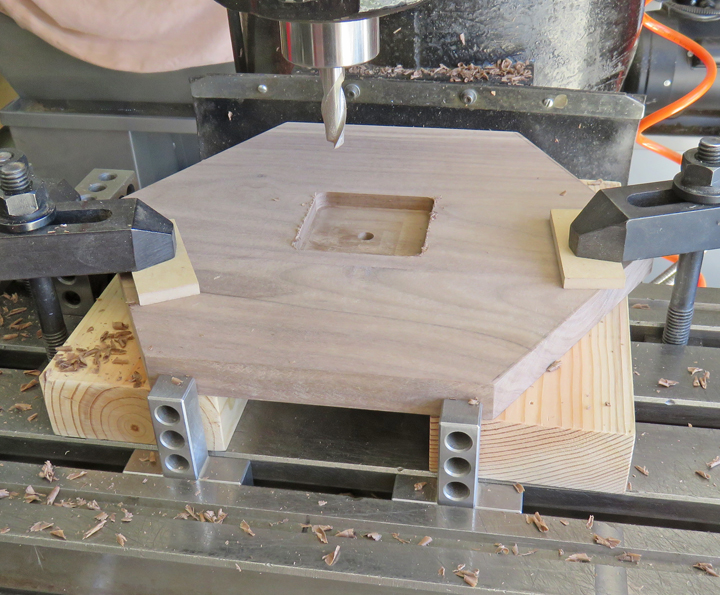

I milled a pocket that was about 5/16" deep along with a hole in the

middle for the shaft. This pocket was necessary because I wanted the

hands to be placed in a certain position within the nuts thickness.

|

|

|

|

1

2

3

4

5 |