|

Cutting Wood Continued

I used my router along with a 1/8" roundover bit on all

the outer edges that face forward. I used two clamps, worked between

them, moved the clamps and repeated the process. This worked out well

and didn't take long.

|

|

|

|

Now it's time to cut my piece to fit into the rabbit. I'll be using 1/4" MDF for a couple of reasons. First, MDF is

very flat and this is important because I want my pattern to sit nice

and flat. Two, I'll be gluing my pattern and again, this will work well. I clamped my straight edge to my work piece but had a

clearance problem with my saw. To fix this, I used my four foot scale

against my straight edge to give me the clearance I needed.

|

|

|

I'll be cutting this sheet with my circular saw but I don't want my piece to fall on the floor. And to prevent that, I've placed a support

under it. Whatever works you know...

|

|

|

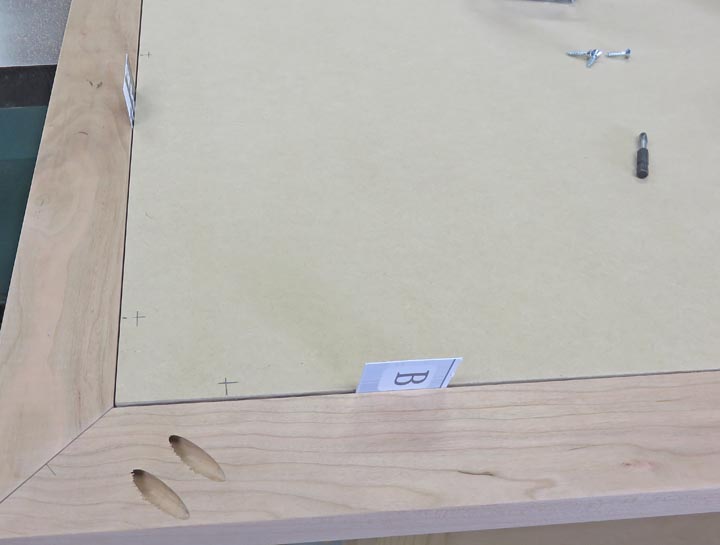

I'm using some cardboard shims to keep the back piece in the middle

while I drill some screw holes. I'll be using some #6 flathead screws

every eight or nine inches which worked out great.

|

|

|

|

Now that the back is screwed in place, it's time to

start making all the pieces that make-up my Chevron pattern. I'll be using

cherry and alder for this. I thought these two species would have a nice

contrast together, with cherry being slightly darker.

I had to move my planer to this unfamiliar location

because my boards were 10 feet long. My back was against the side door

(while taking this picture) and if you notice the out-feed side will

just clear my red tool box.

|

|

|

|

These boards are about 3/8" thick but all I wanted was

the two species to be the same thickness. In other words, just a

clean-up on both sides. This arrangement worked out pretty good so I'll

have to remember this if I work on some long pieces again.

|

|

|

|

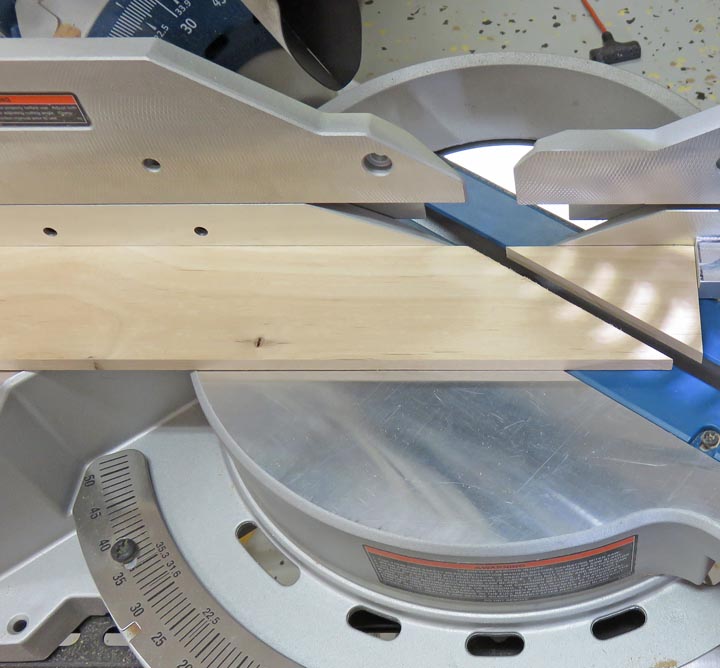

I cut all lengths oversize by about one inch and will bring them to

length using my miter saw when I cut the angles. As you can see I've

already cut the width on my

table saw, which is 2.706. Yes, I know this is a random size but this is

what I came up with when I was drawing it in my CAD system.

|

|

|

The first angle will be 55 degrees and there are a few pieces that will

have this angle at both ends, but not all of them.

|

|

|

|

Here you can see these four pieces will have the same

angle on both ends. But all the rest will have a combination of 55 on

one end and 35 degrees on the other. Also, I'll be alternating species

of wood along the way for some contrast.

|

|

|

Here you can see most of the pieces have the 55 degree angle cut and now

I'll need to start fitting the other end.

|

|

|

|

1

2

3

4

5 |