|

Making Some Bowls Continued

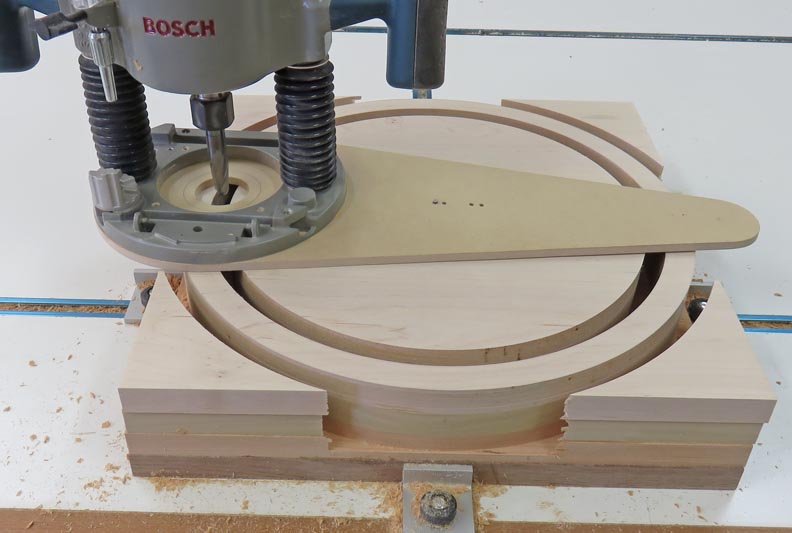

Here I'm working on the inside diameter which isn't to depth here

either.

|

|

|

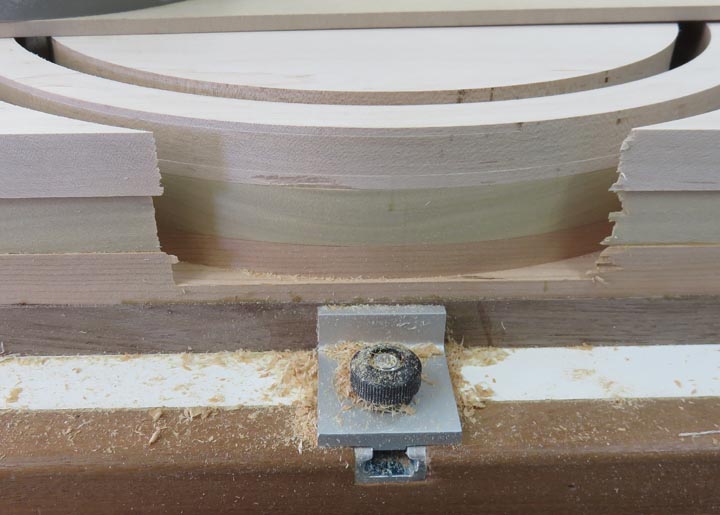

This is how far I was able to cut with my

1/2" cutter. I'll use a flush-cut trim bit on my router table for the outside later.

|

|

|

|

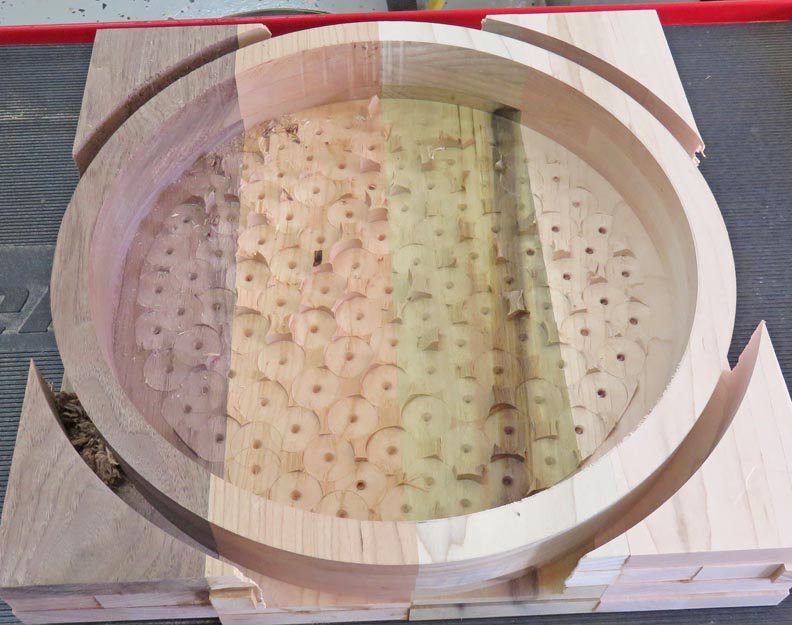

Now that both the I.D and O.D. have been established it's

time to remove all the material in the middle area. I'll be using a 1.0"

diameter Forstner bit and notice the rpm callout on the shank. It says,

"450 max rpm". so I started with about 400 rpm to see how it worked.

|

|

|

This is what one hour of work looks like with that Forstner bit set at

400 rpm. Yeah, I know...way too slow. Now it's time to kick it up a

little.

|

|

|

|

This is what one hour looks like with my mill set to 900 rpm. Much

better to say the least. Note the clamps on each corner now: this is how I

got away with that amount of rpm because of the rigid setup. Otherwise

bad things will happen.

|

|

|

|

I used some pliers to remove all the standing pieces as

they broke off very easy. If I ever do this again, I'll buy a larger

Forstner bit. Also, I still have more than 3/8" to go on the depth

below, which I'll

do with my router and a bowl bit.

|

|

|

Speaking of my router, that's how those lines were made while I was

plunging with my cutter earlier. Now it's time to sand them out.

|

|

|

I could have done this by hand but I decided to use my milling machine

with a sanding drum. This worked great and didn't take long.

|

|

|

|

More Tooling

Now it's time to work on the floor of the bowl so I'm making more

tooling. The size of the MDF is 12" X 18" X 1/4" and

this piece will ride on the top of the bowl while

I'm cutting wood on the floor of the bowl.

|

|

|

What I have here is a 1 1/4" diameter bowl bit with a 1/4" radius

on the bottom, held

in an extension so I can reach the bottom of the floor.

|

|

|

|

1

2

3

4

5

6

7 |