|

Making Some Bowls Continued

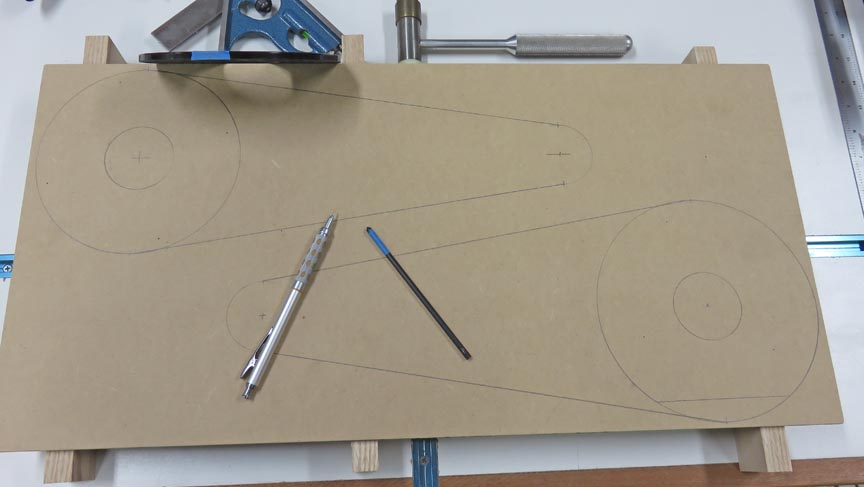

I'm laying out my two different diameters here with my home made compass.

|

|

|

| New Tools

The router I've been using for many years was given to me by my

father-in-law and it's worked pretty good up to this

point. However, it was an older model and ran at a constant 25,000 rpm,

which has been a problem every now and then. This new router by Bosch

has a variable speed dial that will make working with larger diameter

cutters very easy compared to the old one.

Speaking of the old Porter Cable router, I gave that one

to our son Tony, and I told him that I thought his grandfather Jerry, would like

him to have it. And yes he loved it and has used it.

|

|

|

|

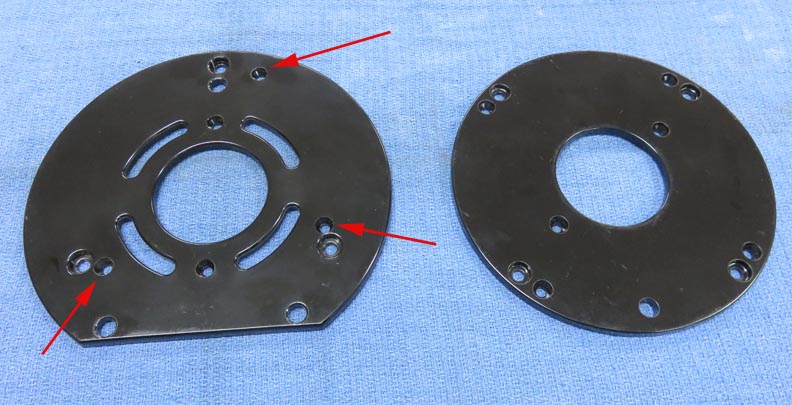

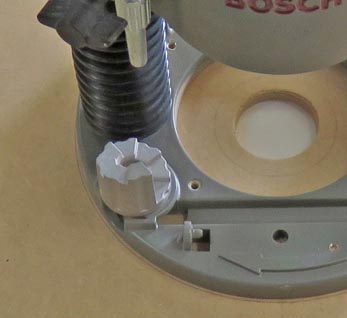

I removed the new router bases because I need to make

some circle cutting jigs. Now I made two different circle cutting

jigs for my old router but those won't fit my new one. Notice the

different hole pattern on these two bases, both of which came with my

new Bosch router

(arrows). I have no idea why they did this in place of making them both

the same. Weird!!

|

|

|

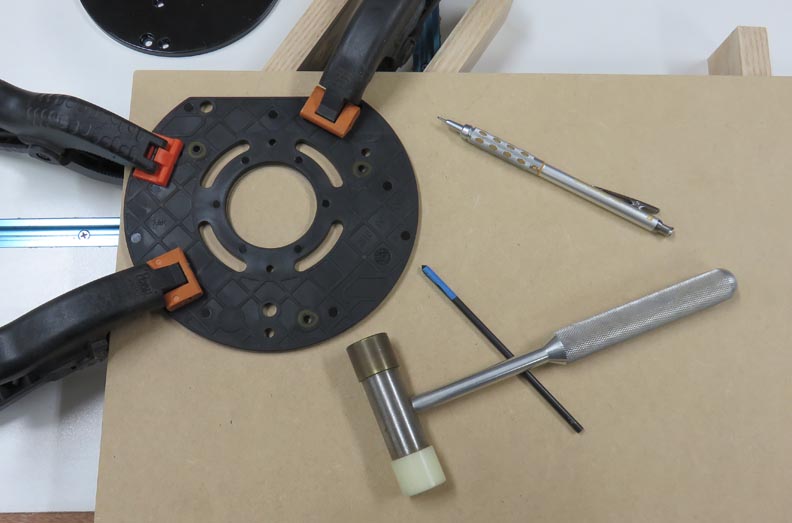

Here I'm transferring the hole pattern onto some 1/4" thick MDF for my

new circle cutting jig. I'll be making one for each base.

|

|

|

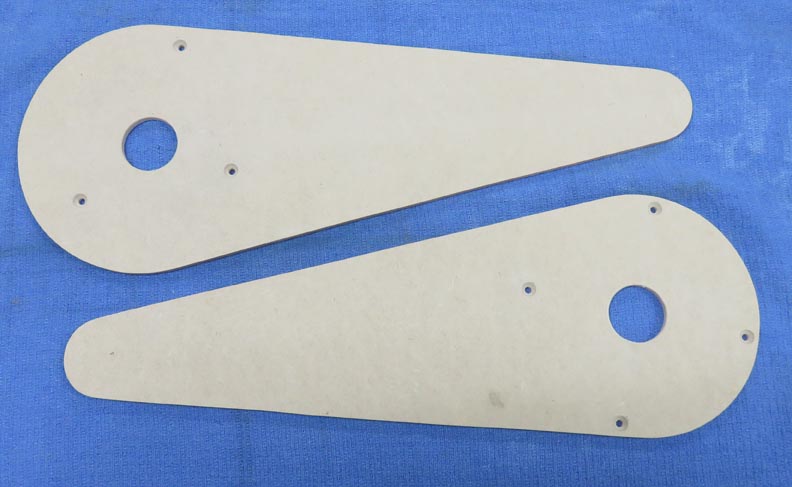

Now that I have them both laid out, I cut them out with a jigsaw.

|

|

|

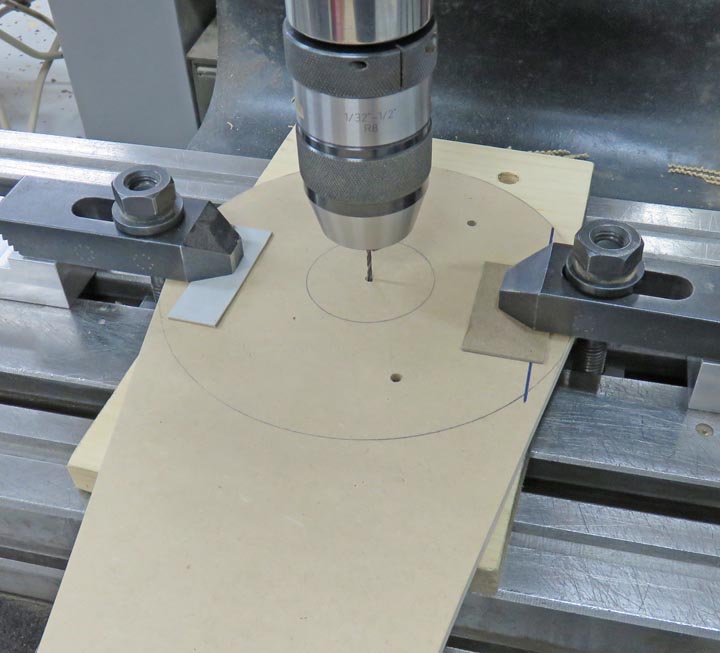

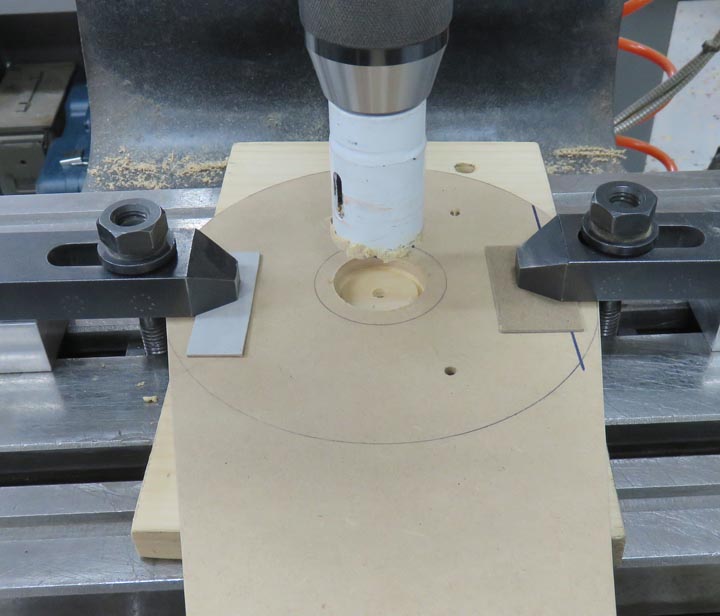

Here I'm drilling a pilot hole in the center, that I'll make larger

next.

|

|

|

I followed the pilot hole with my 1 1/4" hole saw.

|

|

|

After a few minutes of deburring, chamfering holes and sanding, my new jigs

are ready to use.

|

|

|

|

I'm making two cuts with my plunge router, one at 13"

and the other 12 1/4" diameter. Now I wasn't able to go to my final

depth here because my cutter wasn't long enough but I'll address that in a

minute.

|

|

|

That aluminum wheel has 1/8" steps that I used. In all it adds up to 3/4

of an inch. After I made a complete circle with my circle cutting jig,

I'd lift up the cutter, spin the wheel one notch, plunge the cutter back

into my work piece and make another circle.

|

|

|

Here is the magic dial that works really good. The manual has equivalent

rpm numbers that correspond to each number on that red dial. This is a

game changer in my book because the old adage applies in woodworking

just like it does in metal working - speed kills. What do I mean by

this? Smaller cutters do just fine with higher speeds, but not larger

ones. The reason...it's called "Surface Feet per Minute" but that's

another story for another day.

|

|

|

|

1

2

3

4

5

6

7 |