|

2nd. Bandsaw Upgrade Continued

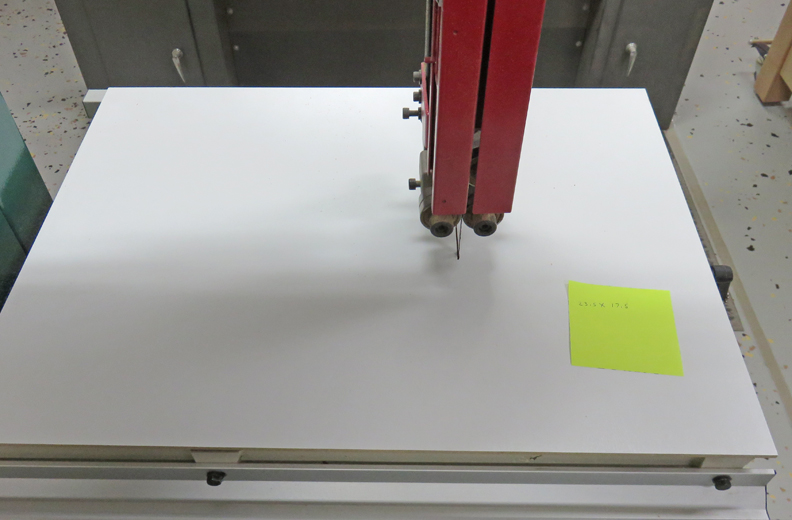

I placed my new slick surface on my bandsaw, cut a slot

in it about halfway through and then stopped. This will act as a 'zero

clearance table insert; like you'd find on a table saw. Now there's no way my

work piece will get hung-up on my table insert any longer.

|

|

|

Next I drew some lines at each corner so I

could round them over. I used my belt sander for this and sanded to the

line.

|

|

|

Next

I sanded all the edges so it will be easy to handle. Now it's time to

make sure it doesn't move while I'm using it.

|

|

|

|

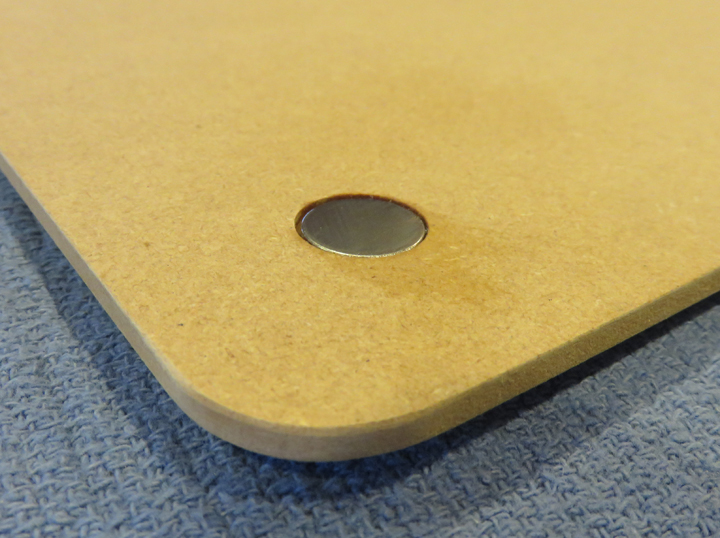

I'm going to use four small magnets to hold this board in

place. That means I'll need to machine some pockets for the magnets to set

in.

I used a 3/4" end mill to produce the pocket that you

see here. However, end mills have an angle ground on the bottom of them and will

leave a high spot in the center while plunging straight down. To get

around this I switched over to a smaller end mill and walked around the

pocket, staying away from the sides. This creates a nice flat surface

when you're finished. The gray color that you see in the pocket is

pencil lead. I colored the entire surface to see where I was cutting

because the depth is only a few thousandths.

|

|

|

|

I bought two different diameter magnets to place in the

pockets because I didn't know which one would work the best. I ended up

using the larger ones, which are 5/8" diameter. The smaller ones are

1/2" diameter and both are 1/16" thick. Side note: the reason

the magnets are so far apart is because they're really strong and kept

moving towards each other.

|

|

|

Here I'm mixing some five minute epoxy to keep the magnets in place.

|

|

|

A few minutes later I had all four magnets bonded. This was

easy to do and should work great to keep my slick new table in place.

|

|

|

|

3rd. Bandsaw Upgrade

One other thing I saw while watching that same video was

the use of a "Stabilizer". What's a stabilizer? Well I didn't know

either until the guy explained it and the more I watched the more I had

to try one. A stabilizer is used with very small blades, 1/4" or less,

and excel at making a very small radius while cutting. And the first

thing I thought of was how nice it would've been if I had this while

making that Christmas gift.

Anyways, I started looking for one and found this model

made for a Grizzly saw. Cool I thought. However, just because something

looks like it will work doesn't mean it will. Case and point:

when I first saw this unit with the hex shank and none of the other

models had one, I figured it was the right part for my saw. Well that's

what I get for thinking!

I was almost ready to send this back but then I started

looking at what I would have to do so I could use it. And after a day or

two I came up with a plan to give it a try after all.

|

|

|

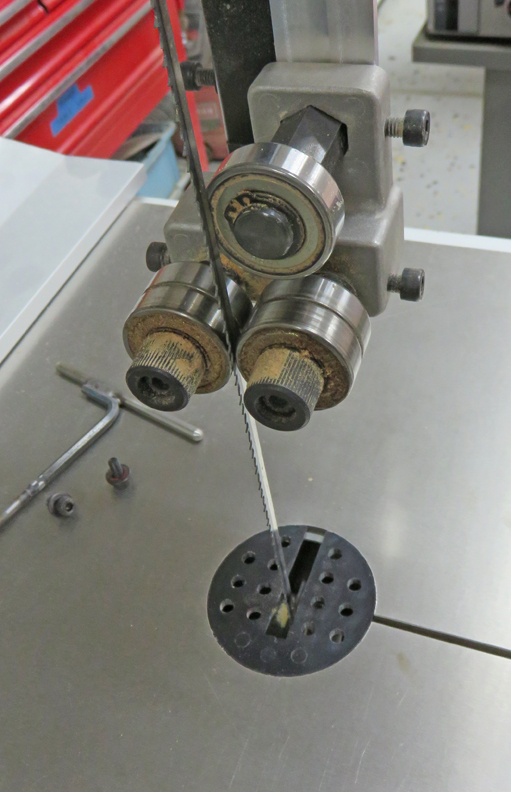

A stabilizer takes the place of of your guide bearings...and I mean all

of them. So what you see below will need to be removed along with the

lower ones as well.

|

|

|

|

When I was looking at the picture online I saw this hex

shank and thought I was good to go. But as you can see the stabilizer's

shank is much smaller. Now if it was larger I could've just machined it

down but it's not. So now what?

|

|

|

|

1

2

3

4

5 |