This is looking at the bottom of the flush cup at the front part of the

stock. The shiny area on the threads is the epoxy. This should hold

great and last for years.

|

|

|

|

New Recoil Pad The next item I'm going to change is the recoil pad. The

pad I chose is made by

Limbsaver and they claim

it will reduce felt recoil by up to 70%. Now I don't know how they make

this claim but they do. All I know is just about anything would be

better than what I had.

|

|

|

|

If you notice in the picture above, this pad is made for

a different gun that I own but on Limbsaver's website, they have a chart

with all their different size pads listed along with all the dimensions and this one was very close to what I

needed. It's a little small in one area and a little large in

another but that doesn't bother me at all. I removed those two tabs

sticking out so they would clear one area that was in the way.

|

|

|

|

Here I'm getting ready to glue on my new pad with the

same epoxy I used earlier. I used some rough sandpaper on the pad and on my rifle stock to make sure they

bonded well. Notice the

steel plate under the recoil pad. I used this as a weight to apply

pressure on top of the pad while things were drying.

|

|

|

|

I let the pad dry overnight and so far everything looks

great. Notice the rough area on the right side of the pad. I tried

sanding this area to make the fit better but I quickly found out I

wasn't doing something right because it stated to tear the rubber

instead of cutting it. At that point, I left it alone and called it a

day.

|

|

|

|

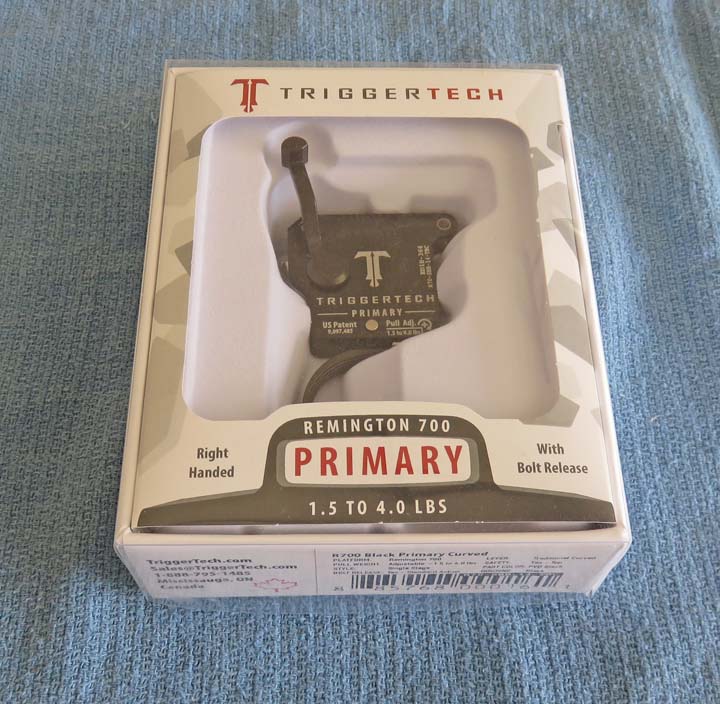

New Trigger

The last thing I'm upgrading is my trigger. My original

is over 40 years old and has seen better days. The one I'm going to use

is made by

Triggertech and they have

a very different design internally. If you get a chance, be sure to take

a look at

how these triggers work

because they're very unique.

Triggertech makes three models for my Remington 700

depending on your needs. And all three models are adjustable for pull

weight. The one I chose is adjustable from 1.5 to 4.0 pounds, which is perfect for

a hunting rifle. I'll probably set mine to three pounds but not any

lighter so it's safe while in the field.

|

|

|

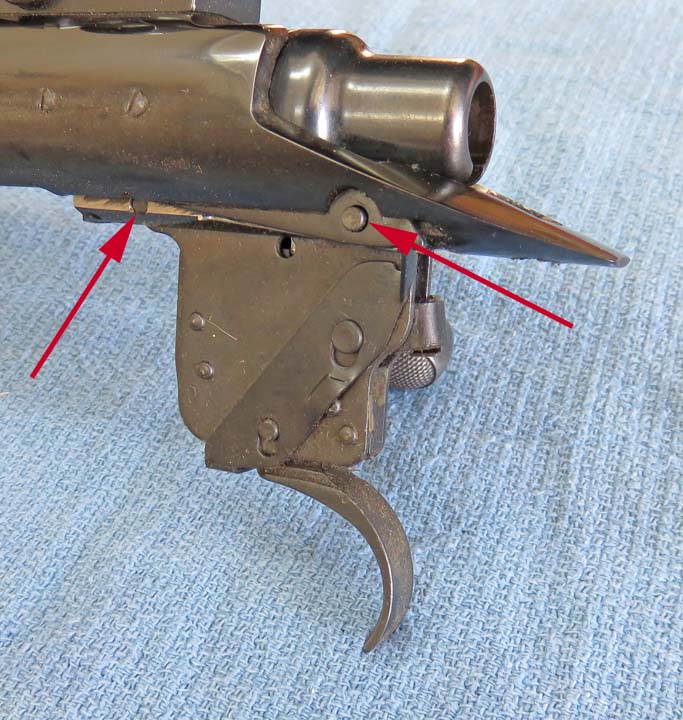

This is my rifles action all naked without a stock. And I haven't seen it like

this for a very long time. Anyways, it's time to replace the trigger.

|

|

|

To remove the trigger you have to tap out those two pins. The one on the

left goes out the opposite side while the one on the right goes to this

side. Once you do that the trigger assembly comes right out.

|

|

|

|

Before I removed anything I checked the pull weight of

the original trigger. It was right at four pounds with my low dollar

trigger pull gage. This was no surprise because I messed with this

trigger many years ago and reduced the pull weight of it. However, I

didn't know what I was doing back then and I'll show you what I'm talking about

soon.

|

|

|

|

If you look close you can see I didn't completely remove the two pins from the

action. And note the pins are sitting in two different directions like I

mentioned earlier. The reason for this is

because the front pin hole is partially blocked by a small area near the top

of it. But the rear pin could be removed from either side. However, if you do it

this way, it holds another part in place while you swap things out. By

the way, the hammer that you see below I made in High School and worked

great for this.

|

|

|

|

1

2

3

4

5 |