|

Cutting The Slots

I'm cutting the slots for the T-Tracks in three steps.

This is necessary for two reasons: One, I'm using a 1/2" cutter and my

T-Track is 3/4" wide. The second reason, taking multiple cuts is much

more forgiving and is much safer. Speaking of multiple cuts, I set the

plunge router to cut about half the depth for the first pass and then

reset it the final one. I'll show you more

in a minute.

As you can see I've clamped the square tubing to my

bench top. However, I'm not able to cut the slot all the way to the ends

because of where my clamps are placed. That means I can only

cut to within about five inches of the ends (like you see below), then

I'll have to move the clamps and cut the remainder after I get this

slot to the 3/4" width first.

|

|

|

|

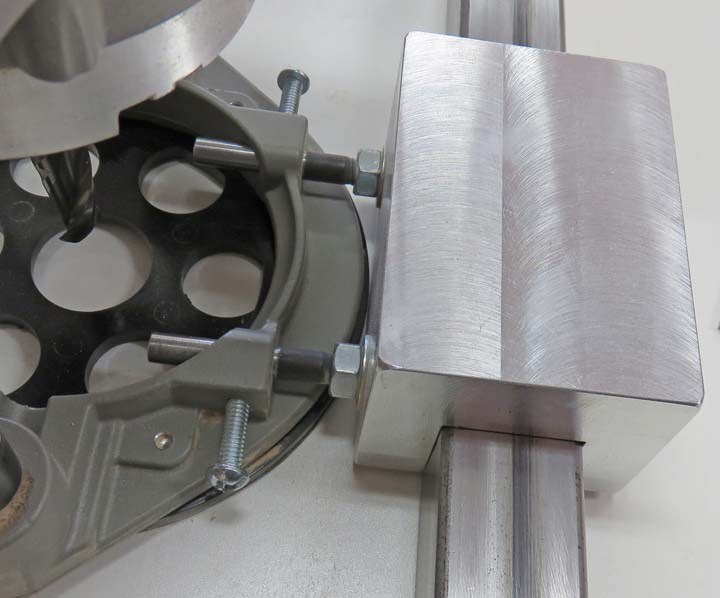

What you see below are two different size shims that I

used to end up at the 3/4" dimension. The slot that you saw above was

set with the 1/8" shim to start with. I placed this between the router

base and the aluminum block and tightened both #12 screws on the base.

This arrangement places the slot near the middle.

|

|

|

In this picture you can see the router base is against the block. This

is for the second of the three passes. And the same thing applies here,

two different depths as I move the router along the square tubing.

|

|

|

So here is what we have so far, cut A is the first cut. Cut B is my

second cut. And the last cut should end up at 3/4" wide, if I did my

math right. The depth is also finished here.

|

|

The third and final pass is set with this custom made shim. The size of

this shim is .270" because I'm using an undersize cutter. If the cutter

was exactly 1/2", I would have used a 1/4" shim here.

|

|

|

|

Here is what it looks like after my third pass. And my

width is exactly what I was after, as the T-track fits great and it

sits just below the surface too. At this point you should have a better

idea of how I went about all this. I did this process at four locations,

which was right over the 2 X 4 stringers on the base (four places). That was the easy

part, because now I want my last slot to be down the middle but I ran

into a snag while doing that.

|

|

|

|

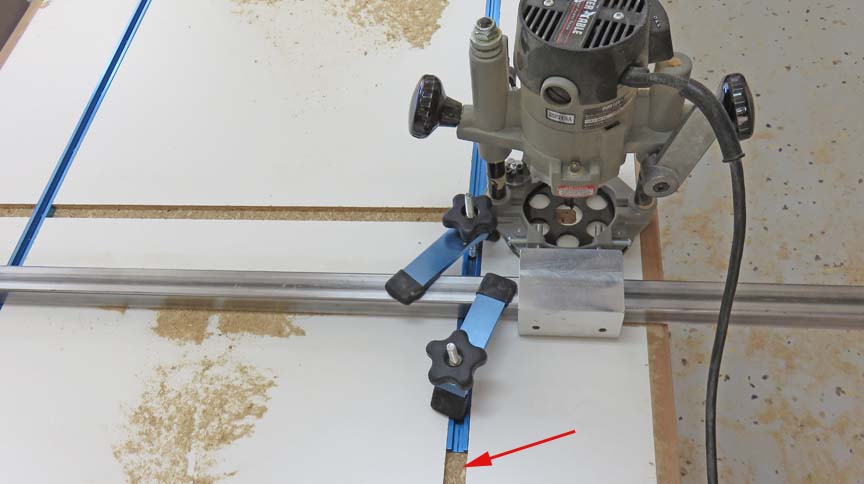

My last slot will be in the middle of the table (short

side). And to cut the slot to within five inches of the edge was the

same as before. However, for those slots I had the luxury of

repositioning my clamps a small amount and then do the last five inches

with no problems. That's not the case here because I'm in the middle of

the table now and there's no edge to move my clamps to.

What I came up with was to install two pieces of T-Track

temporarily (arrow). That way I could use a clamp designed to work with

my T-Track to hold my square tubing like you see below. With these

clamps in place I was able to cut both ends easily. And once I was

finished with these last two cuts, I then removed the temporary T-Track.

Whatever works!

|

|

|

Here are all the slots for the T-track. On a side note, this made a huge

mess because I don't have dust collection built into this router. Next time

I'll use my Craftsman router because that does have provisions for dust

collection.

|

|

|

|

Hardware

Powertec also sells intersections. These came with screws and

are cut with a 45 degree angle on them. This makes them very easy to

install.

|

|

|

|

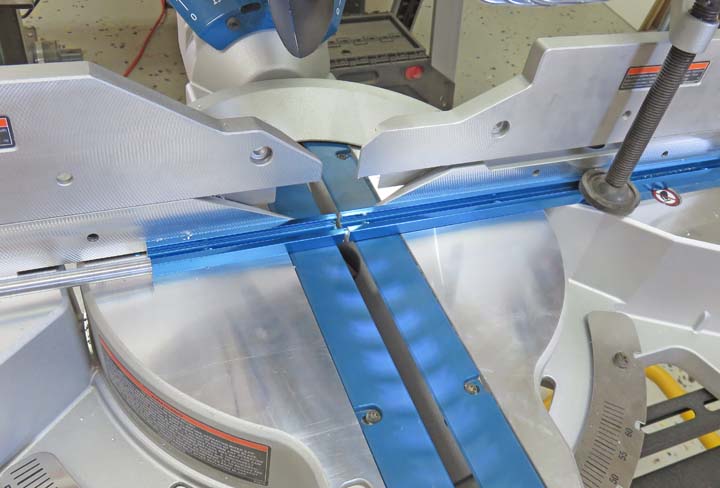

After all the intersection pieces were in place, I was

ready to cut all the remaining pieces. And to do that I cut each piece to length on my miter saw, which worked

great. Note the work stop on the left side, this helped keep each piece

the same length. Safety tip: use a fine tooth blade here and clamping it down while cutting is highly recommended.

|

|

These are all the shorter end pieces and to make sure each one fit

correctly, I labeled each one and I used my milling machine to cut these to

the exact length I needed.

|

|

|

|

1

2

3

4

5

6

7 |