|

The project I'll be making this time is a mobile

workbench. Now this project will be used as a combination workbench,

storage cabinet, out feed table for my table saw, sanding station and

assembly bench. I'll be incorporating a few things that should make

working in the garage a little easier for me. Plus, it should be fun to

make.

Sometimes you make things out of necessity because you

need it. Well, this one has been on my mind for awhile now so you might

say it's 'a necessity'. I'll be using common lumber for most of it and

as you can see I'll be using 4 X 4's for the legs. The stringers will be

2 X 4's along with a plywood/melamine top. I'll also be using plywood to

enclose it with. And the size will be 60" X 36" X 34" tall. With that being said lets get started.

Cutting, Drilling and Assembly |

|

|

|

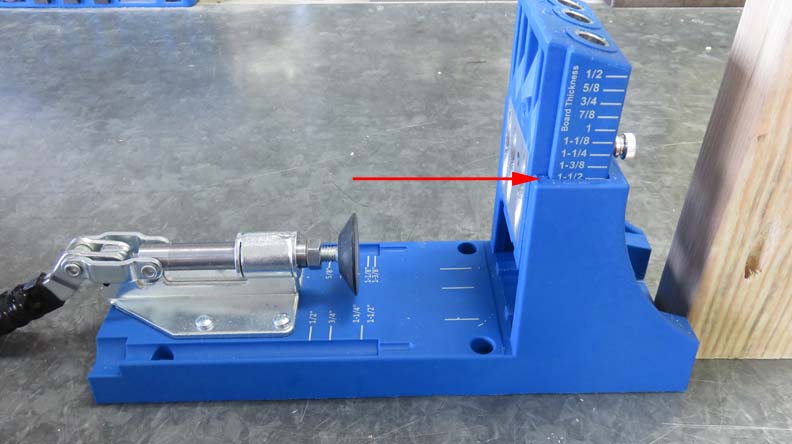

This is a gift that I received for father's day

(2020) from my daughter Angela. This is a

'pocket hole jig' made by

Kreg that makes joining

two pieces of wood together very easy and very strong. Depending on what

size your lumber is, this will dictate how many screws you'll use. In my

case I'll be using three screws per 2 X 4 that are 2 1/2" long.

|

|

|

|

Here you can see I have my Kreg jig set to the thickness

of the wood that I'll be using, which is 1 1/2". This is a very simple system,

easy to use and it works really well. All you do is clamp your work

piece in the jig, set the drill depth and drill your holes.

|

|

|

|

After your holes are drilled, you're ready for assembly.

I clamped my work piece to this leftover piece of melamine setting on

some

saw horses. Once you have things placed where you want them, you insert

a screw into the hole and drive it into your mating piece. The Kreg screws

are special and use a square pocket

in place of a Phillips head screw. Phillips head screws tend to cam-out while you're

tightening them but the Kreg screws don't. This system works great as long as you keep pressure on

the screw while it's being threaded in.

|

|

|

|

Here you can see my finished base, which didn't take

long to put together. The top that will attach later is 10" larger than

the base on both length and width. The reason for that is so I'll have five

inches of overhang all over, meaning I can clamp something near the edges if I

need to. Also notice that you won't see any of the fasteners because

they are all on the inside.

|

|

|

|

The following day I started on the top. What you see

here is a piece of 1/2" plywood that I fastening to some 3/4" melamine.

If you look close you can see some layout lines along with many screws

holding the two pieces together. The layout lines represent where I'll

be installing some T-Track so I placed all my screws around them.

|

|

|

A close-up of the layout lines for the screws and T-Track.

|

|

|

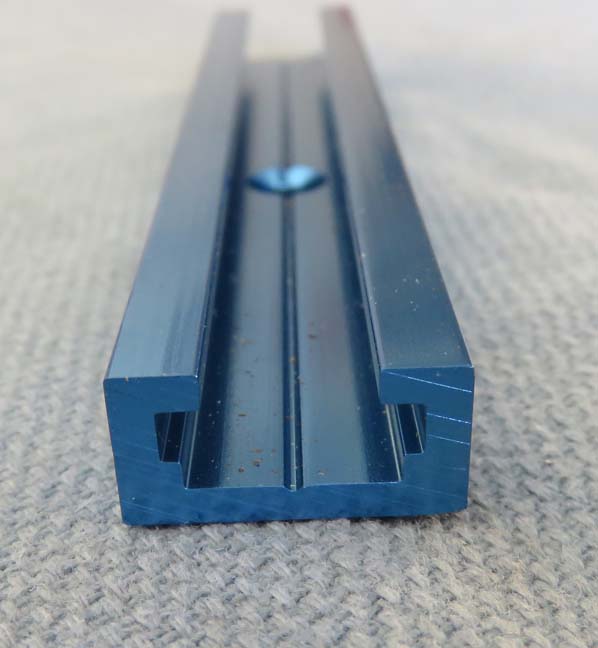

T-Track

Most of the T-track I'll be using is 48" long. It comes with pre-drilled

countersunk holes for # 6 screws, which are placed every four inches apart.

The T-Track is made out of extruded aluminum and they have been anodized blue.

|

|

|

As you can see, these are made by Powertec but a lot of other

manufactures make these as well. However, if you want to save some

money, don't buy the Rockler brand, they cost much more but are just a

different color.

|

|

|

|

This is what the T-track looks like up close. The slot

width will except a 1/4" bolt head which can slide along the inside of

the track with the head of the bolt captured by the smaller/wider groove

so it doesn't spin.

|

|

|

This should give you a good idea of what I was talking

about (left side). The clamp on the right has a different style bolt

head that are specifically made for T-Tracks. And there are all kinds of

T-Track accessories that you can buy, or you can make your own using

1/4" bolts.

|

|

|

1

2

3

4

5

6

7 |