|

What I'm doing here is cutting some 1/4" wooden dowel pins that will be

1" long. To make sure they're all the same length I'm using my mill

stop and my vise to hold them. I'm cutting them with my hacksaw placed

against a steel washer (arrow) so the saw won't damage my vise.

|

|

|

|

I chamfered both ends on my belt sander and now

they're ready to use.

|

|

|

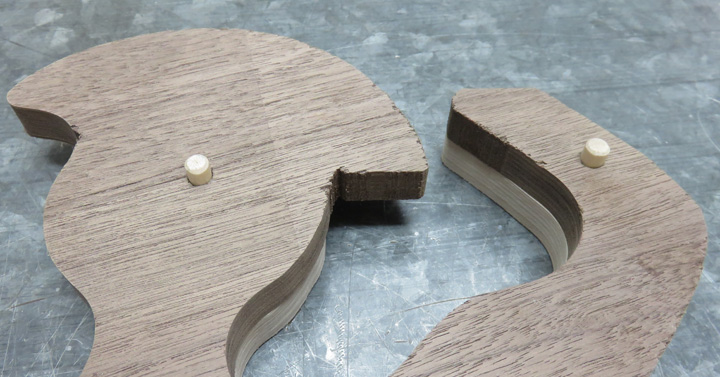

| Here you can see two of the three pieces that will be

glued together like a sandwich later on. But before I can do that I'll need

to sand the periphery while they're together so everything lines up. The plan is to use the

1/4" dowels in the holes that you see here. Using clamps to keep them

together, I drilled one hole, placed a dowel in that hole, and then

moved over to the next position, and repeat.

Once all five holes were drilled in the two pieces, I removed all the

dowels, placed the center of the sandwich over the piece that wasn't

drilled yet, clamped those pieces together and used the drilled holes as a drill guide like you see below. This worked out very well

and everything lined up good.

|

|

|

|

Here is one set all drilled with the dowels in place. I only drilled

halfway through the outside pieces so the holes won't show once I'm

finished.

|

|

|

|

Here is a close-up of the dowels to give you an idea of what I'm doing.

Also notice the right side of the guys head that hasn't been sanded yet.

I'll be dealing with that area next.

|

|

|

This was a lot of work up to this point but it's also been a lot of fun

too. Speaking of fun, the cool part of making a new project (for me) is figuring out what I need to do next, or how

I'm going to make that, gotta do this part before I can do that ...all part the project making

process as it keeps me thinking.

|

|

|

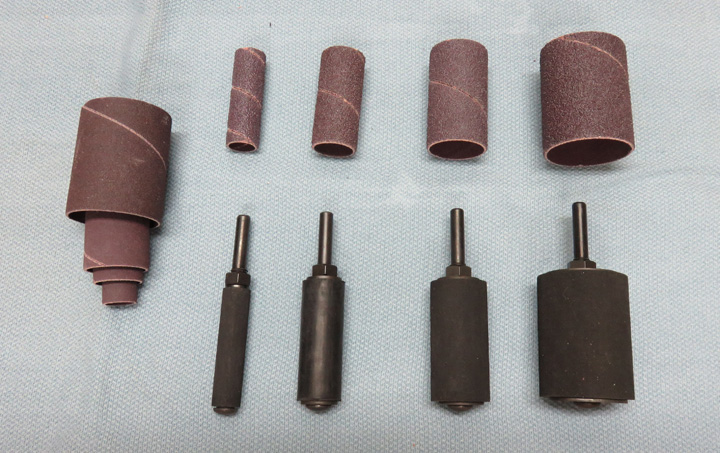

I bought a sanding drum kit online and this should work for sanding the

periphery of the little men. The men (stacked together) are 1 1/2" thick and the new sanding

drums are 2" long. The first sanding drum I used was 1 1/2" long (when I

worked on the individual pieces earlier), not exactly ideal for what I'm

doing here so this is why I bought the longer ones. The sizes are 1/2",

3/4", 1" and 1 1/2" diameters. The kit also came with two sets of drums,

each with a different grit. To make sure I didn't run out of sanding

drums, I also bought a few extras (not shown).

|

|

|

|

I put my sandwich together, along with the five dowels, placed my

sanding drum next to and just below my mill table and started sanding

the perimeter like I did before. I'm using the 1/2" drum here which

worked great for this small narrow area. I used the 1" diameter drum for

everything else.

Notice the radius to the right of the

sanding drum next to his head. If you go back and look three pictures

above, you'll see that area was just a saw-cut (no radius) before using this sanding

drum. I used the same RPM as before, 1800.

|

|

|

After sanding the perimeter, I had an area that I couldn't sand around

because the center of the sandwich was in place. I ended up with a small step

on the guys head which needed to be sanded away (both sides).

|

|

|

In order to sand just the outside pieces of the sandwich, I cut some new

dowels 1/2" long to keep the two pieces aligned. This worked out great

and I was able to remove and blend the step so it looks like it was

never there.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14 |